Product Overview

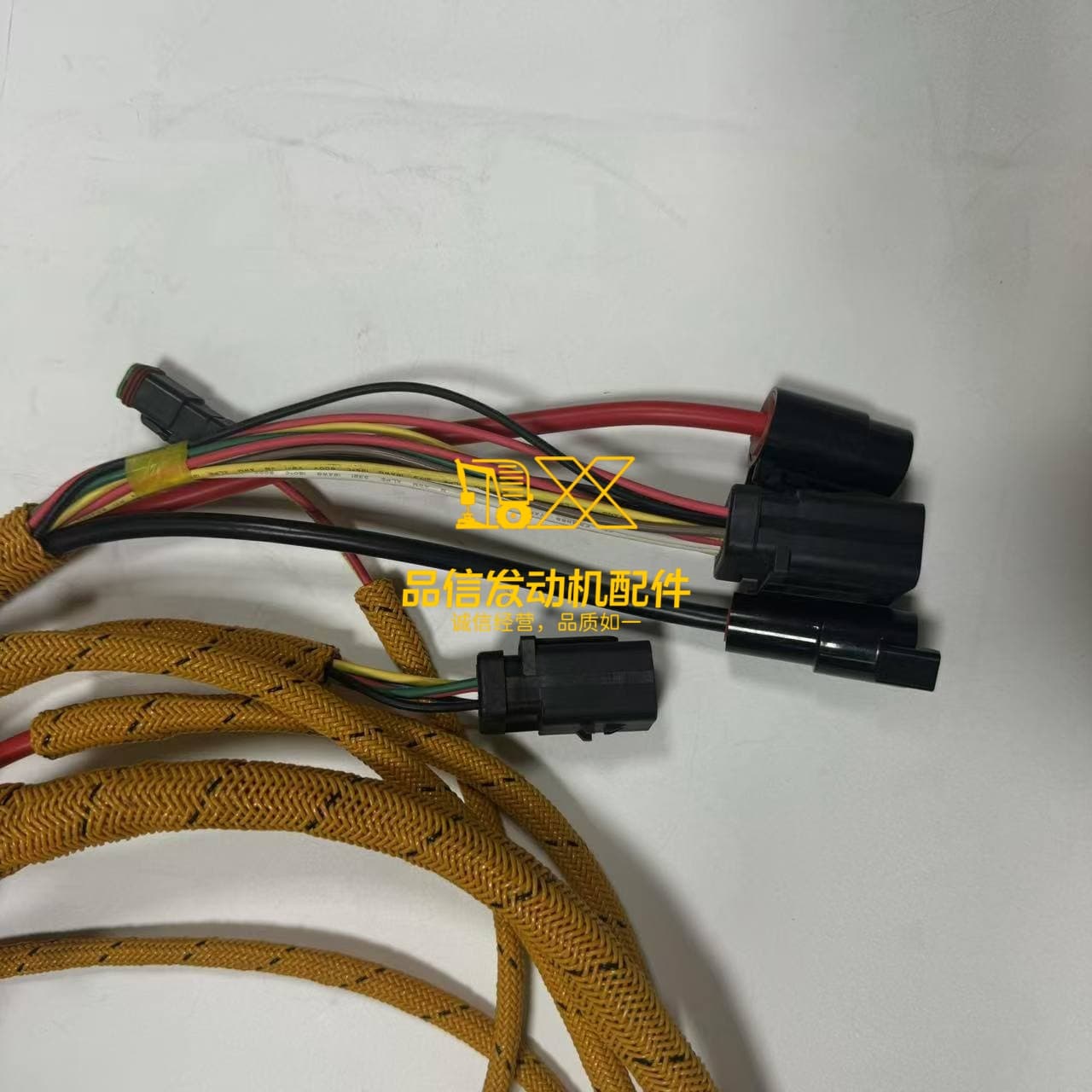

Introducing the genuine quality replacement Wiring Harness 239-5929, specifically designed for a range of powerful Caterpillar CAT engines. This critical component ensures reliable electrical connections throughout your engine system, facilitating optimal performance and communication between various sensors and modules. Manufactured to strict specifications, this harness provides a durable and dependable solution for maintaining or repairing your valuable CAT equipment.

Application Scenarios & Case Analysis

These powerful CAT engines are workhorses in various demanding industries. A reliable wiring harness like the 239-5929 is crucial for their consistent operation.

Common Applications:

Heavy Construction Machinery: Powering large excavators, dozers, wheel loaders, and articulated trucks operating in challenging terrains and conditions.

Mining Equipment: Essential for haul trucks, shovels, and other heavy equipment facing extreme loads and environments.

Power Generation: Used in generator sets providing prime or backup power for industrial, commercial, and remote applications.

Industrial Applications: Driving pumps, compressors, and other heavy industrial equipment.

Marine Propulsion & Auxiliary Power: Providing reliable power for commercial vessels and offshore platforms.

Case Analysis (Illustrative):

Scenario: A mining operation experiences intermittent power loss and sensor errors on a CAT C18-powered haul truck. Diagnostic checks point to a faulty or degraded engine wiring harness.

Analysis: A failing wiring harness can cause signal disruption, leading to incorrect readings from sensors (temperature, pressure, speed) or failure to communicate with the engine control module (ECM). This can result in reduced engine performance, increased fuel consumption, diagnostic trouble codes (DTCs), or even engine shutdown. Replacing the old harness with a new, high-quality 239-5929 harness restores proper electrical connectivity.

Outcome: With the new harness installed, the sensor errors are eliminated, engine performance stabilizes, and the risk of unexpected downtime is significantly reduced, ensuring the truck operates reliably in the demanding mining environment.