Cummins QSB 6.7 Diesel Engine Piston Kit - Superior Performance & Reliability (P/N: 4955160, 4934860)

Product Overview

Ensure the heart of your heavy-duty machinery beats strong with our premium Diesel Engine Piston Kit for the Cummins QSB 6.7 engine. This kit, featuring part numbers 4955160 and 4934860, is engineered to meet or exceed OEM specifications, providing a reliable and durable solution for engine rebuilds and maintenance. Designed for optimal combustion and longevity, this piston kit is crucial for maintaining engine efficiency and power output in demanding applications.

Product Specifications

Part Numbers: 4955160, 4934860

Engine Model: Cummins QSB 6.7

Components Included: Piston, Piston Pin, Snap Rings (Retainers)

Material: High-strength Aluminum Alloy or Steel (depending on specific part number/application)

Surface Treatment: Various coatings for reduced friction and wear resistance

Design: Precisely machined for optimal fit and performance

Compliance: Manufactured to strict quality control standards

Key Advantages

Enhanced Durability: Constructed from robust materials designed to withstand the extreme pressures and temperatures of diesel combustion.

Optimized Performance: Precision engineering ensures proper compression and efficient power transfer, restoring engine performance.

Perfect Fit: Manufactured to OEM specifications for seamless installation and compatibility with your Cummins QSB 6.7 engine.

Reduced Wear & Tear: Advanced coatings minimize friction, extending the life of the piston and cylinder liner.

Reliable Quality: Rigorously tested to ensure consistent, dependable operation in demanding work environments.

Applicable Equipment

This piston kit is designed for equipment powered by the versatile Cummins QSB 6.7 diesel engine, commonly found in:

Construction Machinery (Excavators, Loaders, Dozers, Graders)

Agricultural Equipment (Tractors, Harvesters)

Industrial Power Units

Generator Sets

Material Handling Equipment

Commercial Vehicles (Medium-Duty Trucks)

Marine Applications

Application Scenarios & Case Analysis

The Cummins QSB 6.7 engine is a workhorse across various industries. Replacing pistons is a critical part of engine overhaul or repair when wear, damage, or failure occurs.

Scenario Example: Construction Site Excavator

A construction company relies heavily on excavators powered by the Cummins QSB 6.7 for digging and material handling. After thousands of hours of operation in dusty, high-load conditions, an engine performance issue arises – loss of power and increased oil consumption. Diagnosis reveals excessive wear on the pistons and cylinder liners. Installing this genuine-quality piston kit (4955160/4934860) as part of a full engine rebuild restores the engine's compression and efficiency.

Case Impact:

By using a quality piston kit, the company avoids costly equipment downtime, restores the excavator's digging capacity and fuel efficiency, and extends the overall lifespan of the machine, ensuring project deadlines are met. This highlights the importance of using reliable replacement parts for critical engine components.

Related Products & Applicable Equipment

When undertaking a piston replacement or engine overhaul, consider other components commonly replaced alongside the piston kit:

Cylinder Liners: Often replaced with pistons to ensure a proper seal and compression. Applicable to the same QSB 6.7 powered equipment.

Piston Rings: Essential for sealing the combustion chamber and managing oil. Included in some kits, but also available separately for the QSB 6.7 engine.

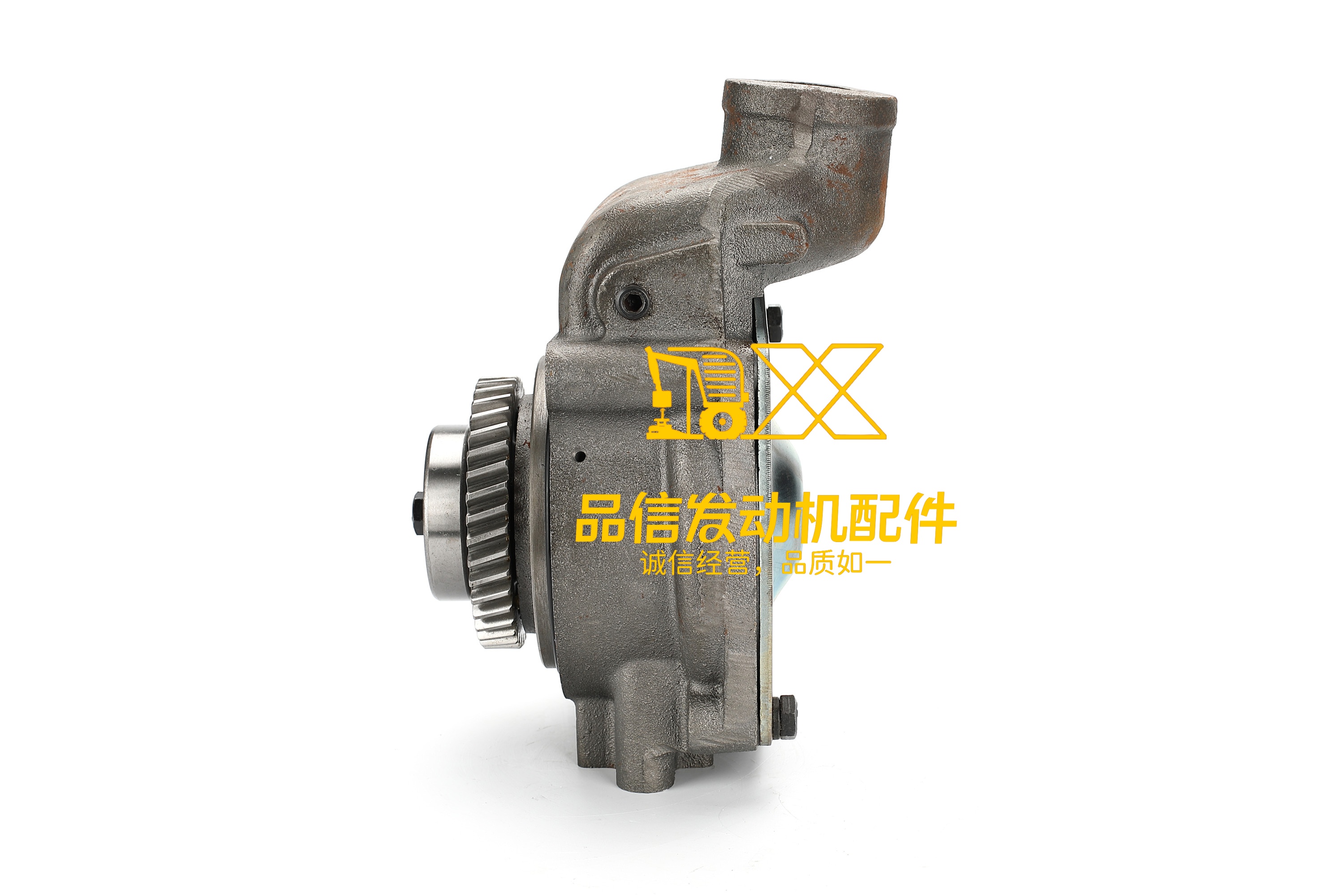

Main & Connecting Rod Bearings: Critical for crankshaft and connecting rod rotation, typically replaced during an overhaul on the QSB 6.7 engine.

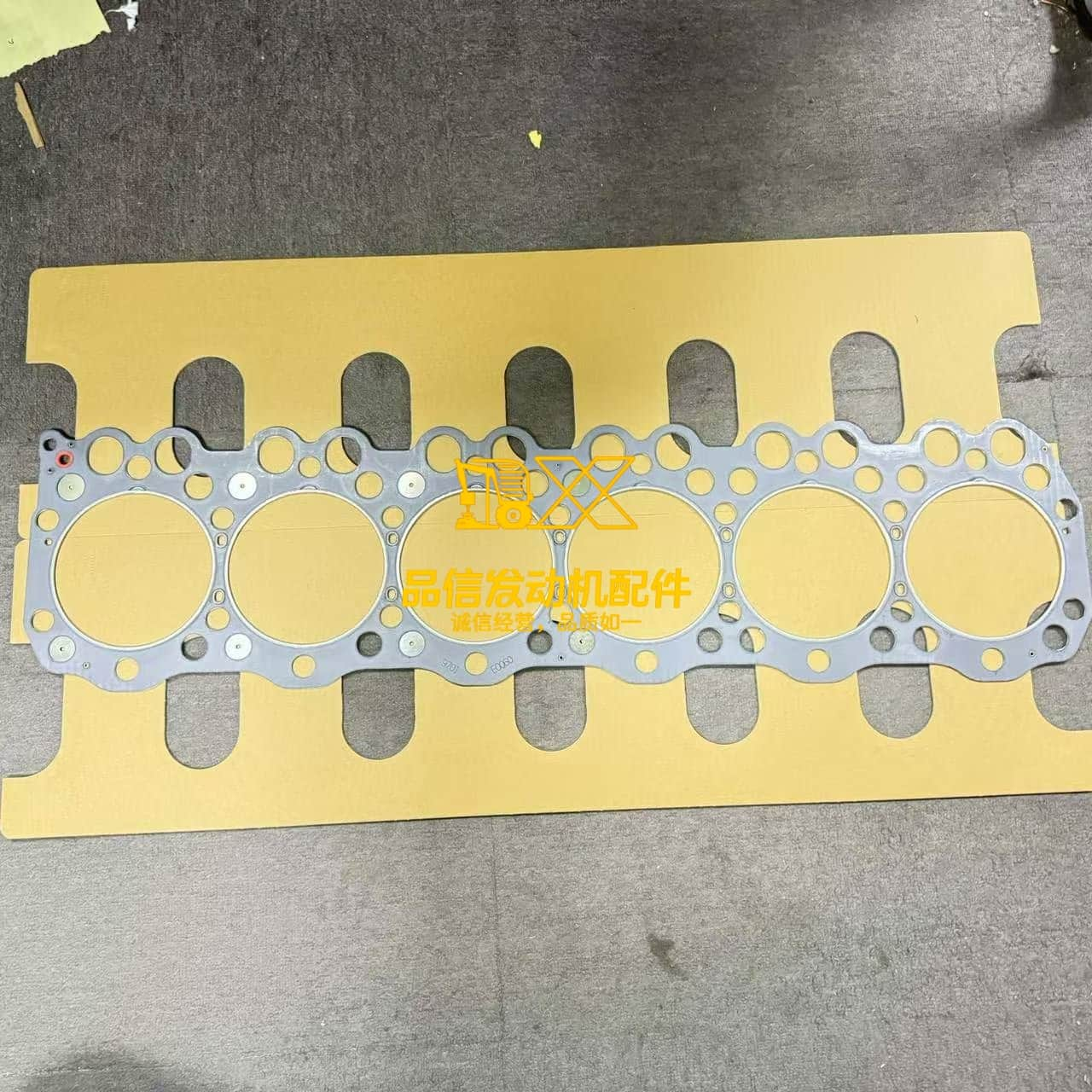

Gasket & Seal Kits: Comprehensive kits needed to reseal the engine after disassembly, applicable to all QSB 6.7 engine repairs.

Engine Valves, Guides, and Seats: Components of the cylinder head that may require attention during a major engine service on applicable QSB 6.7 equipment.

These related parts are vital for a complete and successful engine repair on your QSB 6.7 powered machinery.

Common Installation Issues & Solutions

Proper installation is key to the longevity and performance of your new piston kit. Here are some common issues and how to avoid them:

Issue 1: Incorrect Piston Ring Gap

Problem: Rings installed with too small or too large a gap can lead to poor compression, oil consumption, or ring breakage.

Solution: Always check and file the ring gaps to the specifications provided in the Cummins QSB 6.7 service manual before installing the rings onto the piston.

Issue 2: Contamination

Problem: Dirt or debris entering the engine during installation can cause immediate damage to bearing surfaces or cylinder walls.

Solution: Ensure a spotless work environment. Thoroughly clean all engine components and block passages before assembly. Use clean tools and wear lint-free gloves.

Issue 3: Improper Piston or Ring Orientation

Problem: Pistons or rings installed backward or in the wrong cylinder can cause severe engine damage.

Solution: Pay close attention to directional arrows or markings on piston crowns and rings. Always refer to the service manual for correct placement and orientation for each cylinder of the QSB 6.7 engine.

Issue 4: Incorrect Torque Specifications

Problem: Over- or under-tightening connecting rod bolts can lead to bearing failure or bolt fatigue.

Solution: Use a calibrated torque wrench and follow the specific torque sequence and values provided in the Cummins QSB 6.7 service manual precisely.