Cylinder Liner

190-3562

Suitable

for

Caterpillar

C9

Engine

Part

Product Overview

The Cylinder Liner part number 190-3562 is a critical component designed for Caterpillar C9 engines. It serves as the inner wall of the engine cylinder, providing a durable surface for the piston to travel within. Precision-engineered to meet strict Caterpillar specifications, this liner ensures optimal engine performance, longevity, and efficiency by maintaining proper compression and facilitating effective heat transfer.

Product Parameters

Part Number: 190-3562

Engine Model: Caterpillar C9

Type: Cylinder Liner (Dry Type typically for C9)

Material: High-grade cast iron alloy designed for wear and heat resistance

Inner Diameter (Bore): Standard Caterpillar C9 specification

Outer Diameter: Designed for precise fit within the C9 engine block

Surface Finish: Honed to specific roughness for optimal oil retention and piston ring seating

Compliance: Manufactured to meet or exceed OEM specifications

Advantages and Selling Points

Precision Fit: Engineered for a perfect fit within the Caterpillar C9 engine block, ensuring easy installation and optimal sealing.

Enhanced Durability: Constructed from premium materials resistant to wear, heat, and corrosion, extending engine life.

Optimal Performance: Maintains precise cylinder bore dimensions under extreme conditions, ensuring consistent compression and efficient combustion.

Reduced Oil Consumption: The carefully controlled surface finish promotes proper lubrication and minimizes oil bypass.

Cost-Effective Repair: Replacing a worn liner is often more economical than replacing the entire engine block, offering a vital solution for engine rebuilds.

Reliability: A high-quality replacement part crucial for restoring engine reliability and preventing costly breakdowns.

Applicable Equipment: Caterpillar C9 Engine

The 190-3562 Cylinder Liner is specifically designed for use in Caterpillar C9 engines. The C9 engine is a popular and versatile nine-liter inline 6-cylinder diesel engine known for its power, reliability, and fuel efficiency across a wide range of applications. It is commonly found in various Caterpillar machinery, including but not limited to:

Excavators: Such as certain models of the 330D, 336D.

Dozers: Including models like the D6N, D6T.

Wheel Loaders: Like the 950H, 962H.

Motor Graders: Such as the 12M, 140M.

Articulated Trucks: Certain 725, 730 models.

Soil Compactors: Like the 815F.

Industrial and Petroleum Applications: Powering pumps, generators, and other industrial equipment.

Application Scenarios and Case Analysis

Caterpillar C9 engines and the equipment they power operate in demanding environments worldwide. The 190-3562 cylinder liner plays a vital role in ensuring these machines perform reliably in various challenging applications:

Construction Sites:

C9 powered excavators and dozers are workhorses in construction, used for digging foundations, grading land, and moving heavy materials. These applications involve continuous heavy loads and exposure to dust and debris. A reliable cylinder liner is essential to withstand the constant piston movement and combustion pressures, preventing blow-by and maintaining engine power needed for tough jobs.

Mining Operations:

Articulated trucks and large wheel loaders equipped with C9 engines are common in mines, transporting ore and overburden. Mining environments are characterized by extreme temperatures, heavy vibration, and abrasive conditions. The durability and wear resistance of the 190-3562 liner are crucial here to withstand these harsh factors and ensure the engine provides consistent power for hauling heavy loads over long distances.

Road Building and Maintenance:

C9 powered motor graders are indispensable for creating and maintaining smooth road surfaces. This involves precise, continuous operation under varying loads. The liner's ability to maintain exact bore dimensions is key to ensuring the engine runs smoothly and efficiently, providing the consistent hydraulic power required for fine grading and control.

Case Example: A construction company reported decreasing power and increased oil consumption from a C9 engine in their excavator. Diagnosis revealed a worn cylinder liner causing poor piston ring sealing. Replacing the old liner with the 190-3562 restored engine compression, eliminated excessive oil use, and returned the excavator to full operational efficiency, preventing the need for a much more expensive engine overhaul or replacement.

Related and Similar Products

When performing engine maintenance or a rebuild involving the 190-3562 cylinder liner, other related components of the Caterpillar C9 engine should also be inspected and potentially replaced. These include:

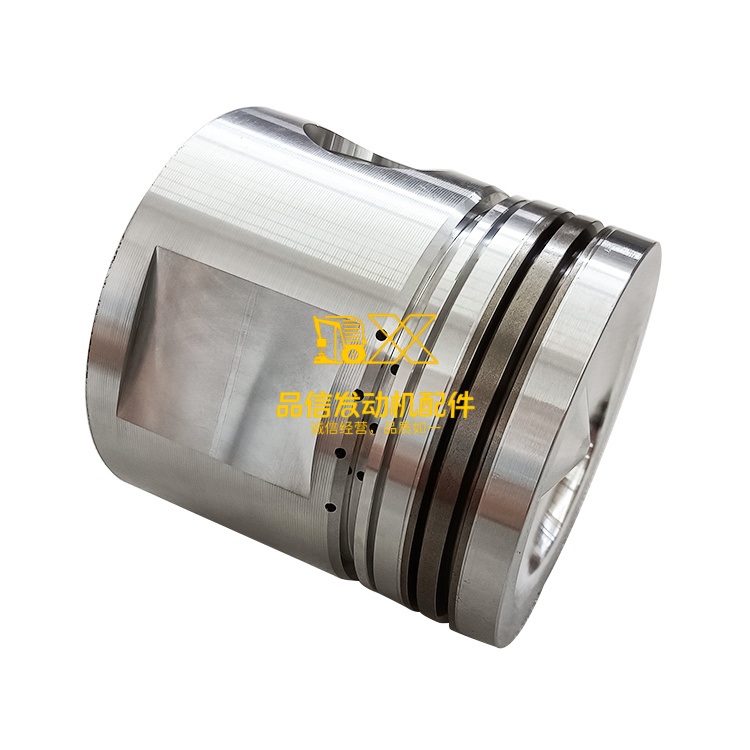

Pistons and Piston Rings: Work directly with the liner to create the combustion chamber seal. Compatible with various C9 engine models.

Engine Bearings (Main and Connecting Rod): Support the crankshaft and connecting rods. Essential for smooth engine rotation in all C9 applications.

Gasket and Seal Kits: Provide necessary seals for a complete engine rebuild. Suitable for Caterpillar C9 engines in excavators, loaders, graders, etc.

Valves, Guides, and Seats: Components of the cylinder head combustion system. Applicable to the cylinder head of C9 engines.

Engine Oil Pump: Circulates oil for lubrication and cooling. Fits Caterpillar C9 engines.

These related parts are also vital for the overall health and performance of the Caterpillar C9 engine across all its applicable equipment and scenarios.

Installation and Maintenance Issues & Solutions

Proper installation and ongoing maintenance are key to maximizing the life and performance of the 190-3562 cylinder liner and the Caterpillar C9 engine. Here are some common issues and their solutions:

Issue: Improper Seating During Installation

If the liner is not seated correctly in the block counterbore, it can lead to inadequate compression, coolant leaks, or block damage.

Solution: Ensure the block counterbore is clean and free of debris or corrosion. Use the correct installation tools and procedures specified in the Caterpillar service manual. Verify liner protrusion is within specifications after installation.

Issue: Cylinder Scuffing or Scoring

Caused by inadequate lubrication, foreign particles, or improper piston ring seating. Results in loss of compression and increased oil consumption.

Solution: Ensure the lubrication system is functioning correctly. Use the recommended engine oil and change intervals. Inspect piston rings for proper installation and condition. Filter intake air effectively. In severe cases, the liner must be replaced.

Issue: Cavitation Erosion

Formation and collapse of coolant bubbles on the liner's outer surface, leading to pitting and eventual leaks. Common in wet liner applications, though less typical for the dry C9 liner but can occur if coolant properties are incorrect.

Solution: Use the correct type and concentration of coolant/antifreeze with appropriate Supplemental Coolant Additives (SCAs) or use an Extended Life Coolant (ELC) as recommended by Caterpillar. Maintain proper cooling system pressure.

Issue: Bore Distortion

Cylinder bore becoming out of round or tapered due to uneven heat distribution, improper torqueing of head bolts, or block issues.

Solution: Ensure cylinder head bolts are torqued correctly following the specified pattern and sequence. Address any cooling system issues causing localized overheating. Inspect the engine block for damage or deformation before liner installation.

Regular engine inspections and adherence to Caterpillar's recommended service intervals are the best preventative measures against these issues.