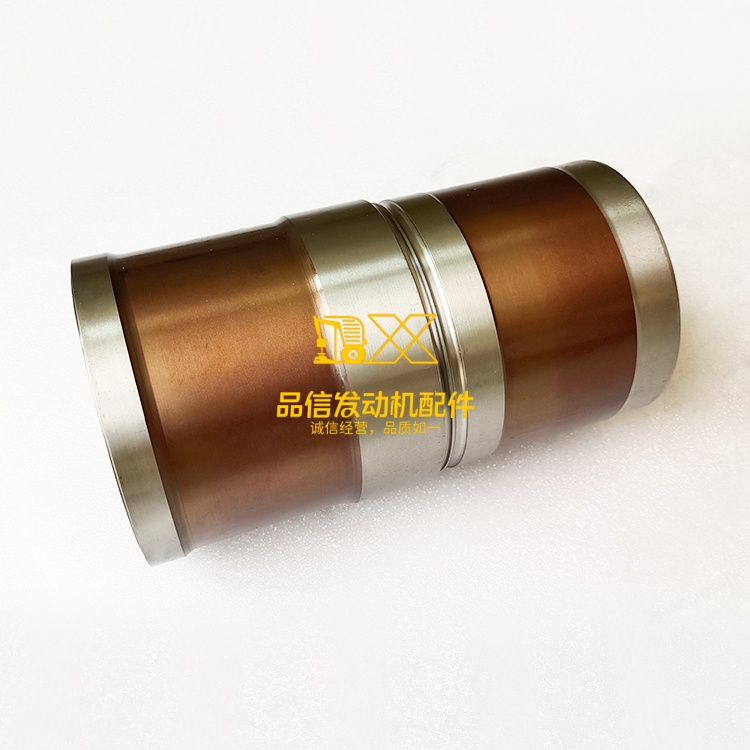

Installing a cylinder liner requires precision and attention to detail to ensure proper engine function and longevity. Here are some common issues encountered during installation and their solutions:

Issue: Improper Bore Cleaning

Residual debris, rust, or old gasket material in the cylinder bore can prevent the new liner from seating correctly, leading to poor heat transfer or liner cracking.

Solution:

Thoroughly clean the cylinder bore using appropriate cleaning tools and solvents.

Inspect the bore for any damage, scoring, or imperfections.

Ensure the counterbore (if applicable for wet liners) is clean and free of debris.

Issue: Incorrect Liner Projection (for wet liners)

If the liner does not project correctly above the block deck, it can lead to head gasket leaks and combustion issues.

Solution:

Measure liner projection accurately using a dial indicator according to the engine service manual specifications.

Use shims or follow specific installation procedures to achieve the correct projection.

Issue: Damaged or Improperly Installed Sealing Rings (for wet liners)

Sealing rings that are cut, twisted, or not properly lubricated can cause coolant or oil leaks.

Solution:

Inspect sealing rings for any damage before installation.

Lubricate the rings and the bore according to the service manual (usually with clean engine oil or specific lubricant).

Carefully install the liner, ensuring the rings seat correctly without twisting.

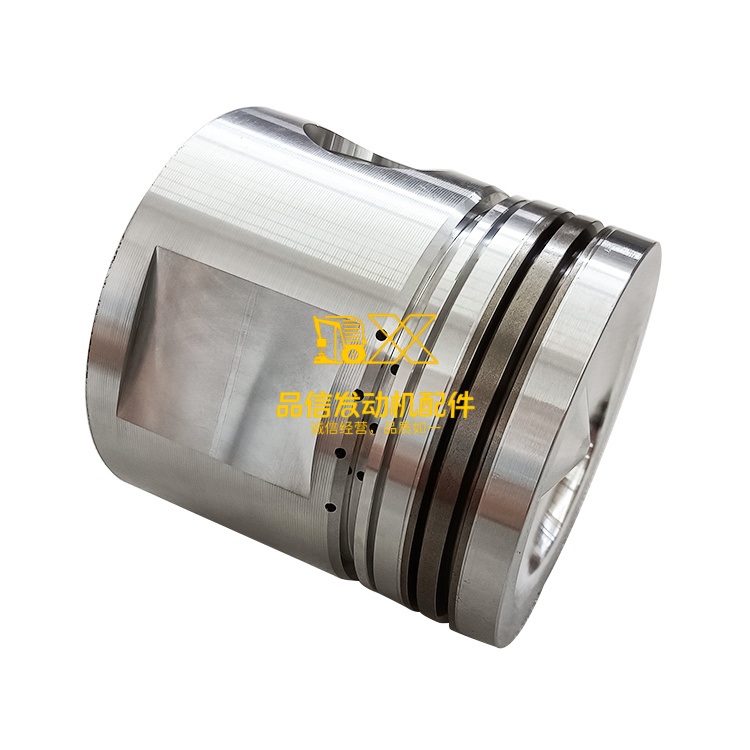

Issue: Forcing the Liner into the Bore

Excessive force can damage the liner, the bore, or the sealing rings.

Solution:

Ensure the liner and bore are clean and properly lubricated.

Use a proper liner installation tool if necessary to guide the liner evenly.

If resistance is met, stop and identify the obstruction rather than forcing it.

Issue: Skipping Pre-installation Checks

Failure to check the new liner for defects or ensure it matches the required specifications can lead to re-work.

Solution:

Always visually inspect the new liner for cracks, damage, or imperfections.

Verify the part number and specifications against the engine requirements.

Perform trial fitting (if recommended) without sealing rings to check for proper seating.

Always refer to the specific Cummins N14 engine service manual for detailed installation procedures, torque specifications, and special tool requirements.