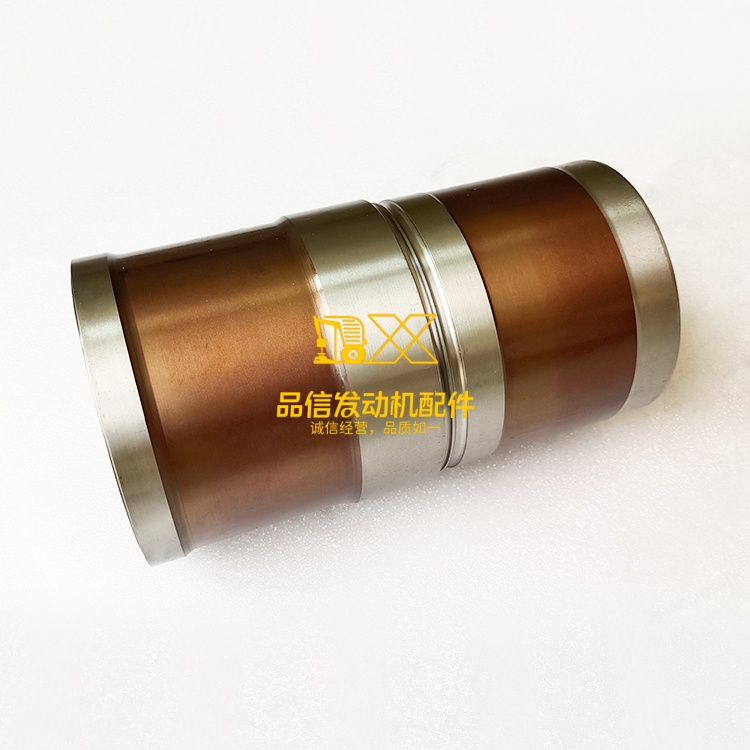

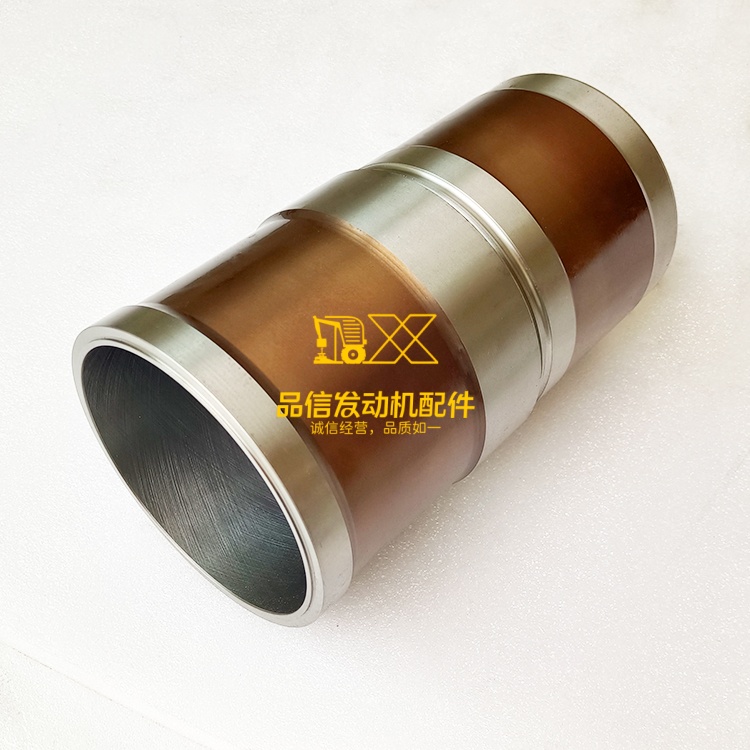

Genuine Cummins Engine ISL9.5 Liner Kit / Cylinder Liner 5290937

Product Introduction

Ensure the peak performance and longevity of your Cummins ISL9.5 engine with the Genuine Cummins Engine Liner Kit / Cylinder Liner, part number 5290937. This critical component is manufactured to Cummins' exacting standards, designed for a perfect fit and optimal function within your engine's combustion chamber. Using genuine parts is essential for reliable engine rebuilds and maintenance, preventing costly downtime and ensuring your equipment operates efficiently.

Product Parameters

Part Number: 5290937

Engine Model: Cummins ISL9.5

Type: Cylinder Liner / Liner Kit

Condition: New, Genuine Cummins Part

Material: High-Quality Alloy (Meeting Cummins Specifications)

Purpose: Forms the cylinder wall within the engine block

Product Advantages & Selling Points

Guaranteed Genuine Cummins Quality: Manufactured by Cummins, ensuring reliability and performance.

Precise Fit and Finish: Engineered to exact OEM specifications for seamless integration.

Optimal Engine Performance: Maintains correct cylinder dimensions for proper combustion and efficiency.

Maximum Durability: Constructed from high-quality materials resistant to wear and heat.

Reduces Risk of Failure: Genuine parts minimize the chance of premature wear or catastrophic engine damage.

Ensures Longevity: Extends the service life of your Cummins ISL9.5 engine.

Applicable Equipment

The Genuine Cummins Engine ISL9.5 Liner Kit / Cylinder Liner 5290937 is designed for use in equipment powered by the Cummins ISL9.5 engine, commonly found in:

Construction Equipment (e.g., Excavators, Wheel Loaders, Cranes)

Buses and Coaches

Medium to Heavy-Duty Trucks

Agricultural Machinery

Various Industrial Applications

Application Scenarios & Case Analysis

The Cummins ISL9.5 engine is a workhorse in demanding applications. Replacing cylinder liners with genuine Cummins part 5290937 is crucial during major overhauls or when performance issues arise due to cylinder wear.

Scenario: Heavy-Duty Trucking

A fleet of trucks operating long-haul routes rely on their Cummins ISL9.5 engines for consistent power and fuel economy. After accumulating high mileage, standard wear affects cylinder compression.

Case Analysis: Using genuine 5290937 liner kits during scheduled engine rebuilds restores the engines to their original specifications. This results in improved fuel efficiency, increased power output, reduced oil consumption, and significantly extends the operational life of the trucks, minimizing unexpected breakdowns and maximizing fleet profitability. Non-genuine parts might fit, but often lead to faster wear, poor sealing, and ultimately premature engine failure.

Scenario: Urban Bus Operations

City buses with ISL9.5 engines face stop-and-go traffic and varied passenger loads, putting stress on engine components. Regular maintenance is key to meeting emission standards and ensuring reliable service.

Case Analysis: Incorporating genuine Cummins 5290937 liners into their maintenance and rebuild programs ensures the buses maintain optimal combustion efficiency, crucial for lower emissions and better fuel economy. This adherence to genuine parts guarantees engine reliability for demanding urban routes and helps the transit authority meet stringent environmental regulations, providing dependable public transportation.

Related & Similar Products

When performing engine maintenance or rebuilds, other related components are often replaced along with the cylinder liners. These genuine Cummins parts are also available and applicable to the same ISL9.5 engine and equipment:

Piston Kits: (Piston, Piston Rings, Piston Pin)

Piston Ring Sets: Ensure proper sealing and oil control.

Engine Bearing Sets: (Main Bearings, Connecting Rod Bearings, Camshaft Bearings)

Engine Gasket Kits: (Upper, Lower, or Full Set) for sealing engine components.

Engine Valves and Guides: For the cylinder head.

Using genuine Cummins parts for all related components ensures system compatibility and maximizes the overall engine's performance and lifespan.

Common Installation Issues & Solutions

Proper installation of cylinder liners is critical. Here are some common issues and their solutions:

Issue 1: Incorrect Liner Protrusion

If the liner sits too high or too low relative to the deck surface, it can cause improper cylinder head sealing or piston damage.

Solution: Always measure liner protrusion using a precise dial indicator. Ensure it falls within the specifications provided in the Cummins service manual. Use correct shims or counterbore repair if necessary.

Issue 2: Damage to Liner or Block Bore During Installation

Forcing the liner, or having debris in the bore, can cause scoring or cracks.

Solution: Thoroughly clean the cylinder block bore before installation. Use specialized liner installation tools designed for the ISL9.5 engine. Lubricate the liner and bore appropriately according to the service manual. Install slowly and evenly.

Issue 3: Improper Sealing Leading to Leaks (Coolant or Oil)

Incorrectly installed or damaged seals, or issues with the counterbore, can lead to leaks.

Solution: Ensure the counterbore is clean, smooth, and undamaged. Use *new* and correct liner seals every time. Position seals correctly in their grooves. Apply sealant sparingly only if specified by the service manual. Torque cylinder head bolts in the correct sequence and specification to ensure proper clamping force and seal compression.