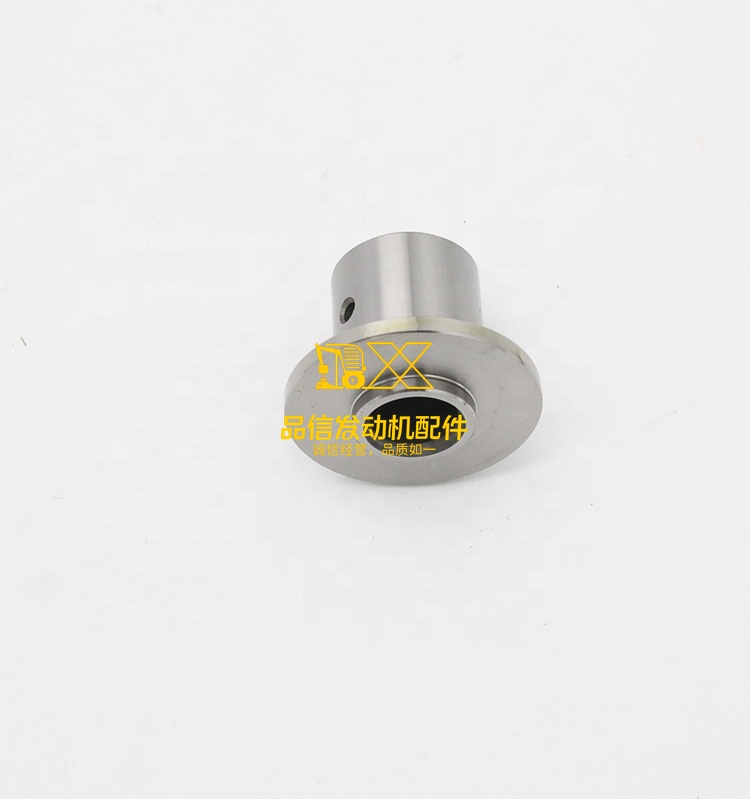

E ngine P art C 5717327 / 5717327

Product Overview

Introducing the high-quality engine part, specifically designed for the Cummins 6CT8.3 engine. This crucial component, identified by part numbers C5717327 and 5717327, is vital for maintaining the optimal performance and reliability of heavy-duty engineering machinery. Ensure your equipment operates smoothly with this durable and reliable part.

Product Parameters

Part Numbers: C5717327, 5717327

Applicable Engine Model: Cummins 6CT8.3

Type: Engine Component (Specific type may vary - common parts include injectors, pumps, filters, etc. Assuming a general critical engine part)

Condition: 100% New / Aftermarket Replacement

Material: (Assuming standard material for engine parts, e.g.) High-Grade Alloy Steel / Durable Composite

Quantity: 1pc

Key Advantages and Selling Points

Perfect Compatibility: Engineered specifically for the Cummins 6CT8.3 engine, ensuring a perfect fit and seamless integration.

High Durability: Manufactured from robust materials to withstand the demanding conditions of heavy engineering machinery operation.

Reliable Performance: Restores or maintains peak engine performance, contributing to fuel efficiency and power output.

Quality Assurance: Produced to meet or exceed OEM specifications, providing a reliable aftermarket solution.

Cost-Effective Solution: Offers a high-quality alternative to OEM parts without compromising on performance.

Applicable Equipment

This part is applicable to various types of engineering machinery that are equipped with the Cummins 6CT8.3 engine. This commonly includes:

Excavators

Wheel Loaders

Bulldozers

Motor Graders

Drilling Rigs

Agricultural Machinery

Mining Equipment

Equipment from major manufacturers often utilizes this reliable engine model, making this part applicable across a wide range of heavy machinery in the field.

Application Scenarios and Case Analysis

Engineering machinery powered by the Cummins 6CT8.3 engine is deployed in demanding environments globally. The part C5717327 / 5717327 plays a vital role in ensuring the continuous operation of these machines in critical applications such as:

Construction Sites: Excavators and loaders are integral to site preparation, digging foundations, and material handling. A failing engine part can halt operations, causing costly delays. Replacing a worn C5717327 ensures the engine runs efficiently, preventing breakdowns during crucial project phases.

Mining Operations: Heavy-duty trucks and loaders operate continuously in harsh, dusty conditions. The 6CT8.3 engine provides the necessary power and reliability. A critical part like C5717327 ensures the engine withstands the extreme stress, minimizing downtime in remote mining locations where repairs are challenging.

Road Building: Graders and pavers rely on consistent engine performance for smooth and accurate work. Engine reliability, supported by quality internal parts, is paramount for meeting project deadlines and quality standards in road construction.

Ensuring this specific part is in good condition is crucial for the overall health and operational readiness of machinery in these intense working environments.

Related and Similar Products

For complete maintenance and repair of the Cummins 6CT8.3 engine, consider these related products often used alongside C5717327 / 5717327:

Fuel Injectors (Ensures proper fuel delivery)

Oil Filters & Fuel Filters (Crucial for engine longevity)

Gasket Kits & Seals (Prevents leaks)

Water Pumps (Maintains engine temperature)

Turbochargers (Boosts engine power)

These parts are also applicable to the same range of engineering machinery utilizing the Cummins 6CT8.3 engine, providing a comprehensive solution for engine maintenance.

Common Installation Issues and Solutions

Proper installation is key to the performance and lifespan of the part C5717327 / 5717327. Here are some common issues encountered during installation and their solutions:

Issue: Incorrect fitting or alignment.

Solution: Always refer to the engine service manual for specific installation instructions, torque values, and sequence. Ensure mating surfaces are clean.

Issue: Leaks after installation (e.g., oil, fuel, coolant).

Solution: Verify that all seals, gaskets, and O-rings are correctly seated and are in good condition. Tighten bolts to the specified torque using a torque wrench.

Issue: Contamination during installation.

Solution: Work in a clean environment. Ensure the part and surrounding components are free from dirt, debris, or foreign particles before and during installation.

Issue: Electrical connection problems (if applicable to the specific part type).

Solution: Ensure all electrical connectors are clean, properly seated, and securely fastened.

If you are unsure about the installation process, it is highly recommended to seek assistance from a qualified technician.