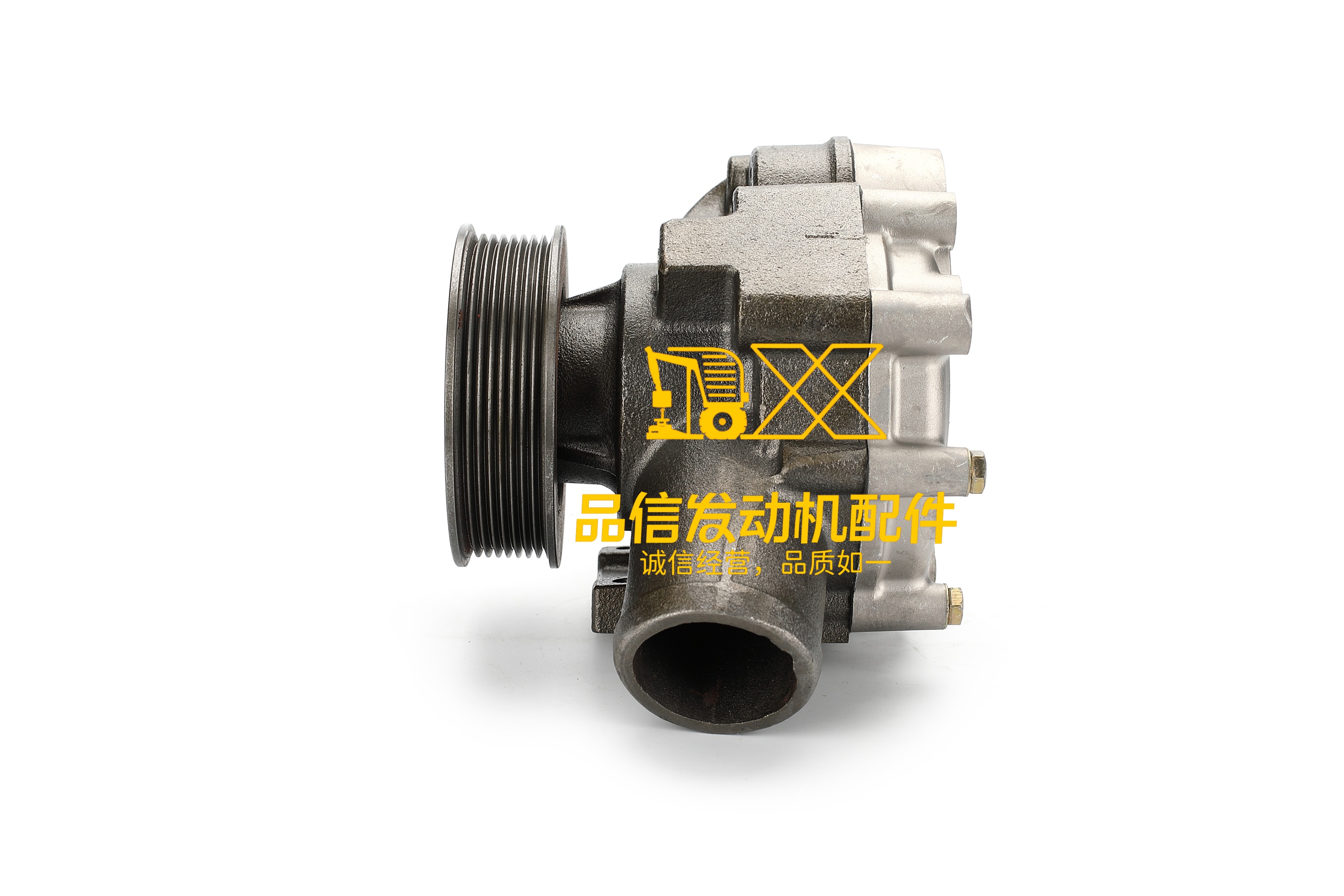

Water Pump 352-2109 for Caterpillar Engine CAT C7 C9 C9.3High-Quality Water Pump 352-2109 for Caterpillar Engines

Ensure optimal cooling for your heavy-duty machinery with our reliable Water Pump 352-2109. This aftermarket water pump is specifically designed to be a direct replacement for Caterpillar part number 3522109. It is compatible with a range of Caterpillar engines, including the CAT C7, CAT C9, and CAT C9.3 models. Keep your Caterpillar C7 engine, Caterpillar C9 engine, or Caterpillar C9.3 engine running smoothly and efficiently with this essential component.

Keywords for Search Engines

Caterpillar C7 water pump

Caterpillar C9 water pump

Caterpillar C9.3 water pump

352-2109 water pump

3522109 water pump

CAT C7 engine water pump

CAT C9 engine water pump

CAT C9.3 engine water pump

Caterpillar engine parts

Aftermarket Caterpillar water pump

Guangzhou Pinxin Engine Co., Ltd. Main Products Keywords

Caterpillar C4.2 engine assembly

Caterpillar C4.4 engine parts

Caterpillar C6.4 diesel engine

Caterpillar C7 engine block

Caterpillar C7.1 fuel injector

Caterpillar C9 crankshaft

Caterpillar C9.3 turbocharger

Caterpillar C13 cylinder head

Caterpillar C15 piston

Caterpillar C18 oil pump

Random Caterpillar Part Explanations

The Caterpillar 3306 fuel injection pump is a critical component responsible for delivering the precise amount of fuel to the engine cylinders at the correct time. It is installed on the Caterpillar 3306 engine, commonly found in Caterpillar 3306 generator sets.

The Caterpillar 3406 turbocharger increases the power and efficiency of the engine by forcing more air into the combustion chamber. It is located on the exhaust manifold of a Caterpillar 3406 engine, often used in Caterpillar 3406 trucks.

The Caterpillar 3408 camshaft controls the opening and closing of the engine's intake and exhaust valves. It is situated within the cylinder block of a Caterpillar 3408 engine, which can be found in Caterpillar 3408 marine engines.

The Caterpillar 3512 piston ring seals the combustion chamber, preventing gases from escaping and oil from entering. Multiple piston rings are fitted around each piston in a Caterpillar 3512 engine, commonly used in Caterpillar 3512 mining trucks.

The Caterpillar 3516 cylinder liner is a sleeve that fits inside the engine block and forms the cylinder bore. Each cylinder in a Caterpillar 3516 engine has a cylinder liner, often seen in Caterpillar 3516 generator sets.

The Caterpillar C4.2 starter motor is an electric motor that cranks the engine to start it. It is mounted on the side of the Caterpillar C4.2 engine, typically found in Caterpillar C4.2 excavators.

The Caterpillar C4.4 alternator produces electrical power to charge the battery and run the vehicle's electrical systems. It is attached to the front of the Caterpillar C4.4 engine, commonly used in Caterpillar C4.4 loaders.

The Caterpillar C6.4 exhaust manifold collects exhaust gases from the engine cylinders and directs them to the exhaust system. It is bolted to the cylinder head of a Caterpillar C6.4 engine, often used in Caterpillar C6.4 graders.

The Caterpillar C7 intake valve allows air to enter the engine cylinder during the intake stroke. Each cylinder in a Caterpillar C7 engine has at least one intake valve, commonly found in Caterpillar C7 bulldozers.

The Caterpillar C7.1 oil filter removes contaminants from the engine oil, keeping it clean and prolonging engine life. It is usually located on the side of the Caterpillar C7.1 engine, often used in Caterpillar C7.1 backhoe loaders.

Random Caterpillar Part Explanation Example

The Caterpillar 345D fan motor drives the cooling fan, which helps regulate the engine temperature. It is located within the cooling system of a Caterpillar 345D excavator.

Chinese: 卡特彼勒 345D 风扇马达驱动冷却风扇,有助于调节发动机温度。它位于卡特彼勒 345D 挖掘机的冷却系统中。

Russian: Вентиляторный мотор Caterpillar 345D приводит в действие вентилятор охлаждения, который помогает регулировать температуру двигателя. Он расположен в системе охлаждения экскаватора Caterpillar 345D.

Common Knowledge about Caterpillar Engines

Q: What are some common signs of a failing water pump in a Caterpillar engine?A: Common signs include engine overheating, coolant leaks (often from the front of the engine), a noisy water pump (whining or grinding sounds), and low coolant levels.

Q: How often should I replace the water pump in my Caterpillar engine?A: The lifespan of a water pump can vary depending on usage and maintenance. However, it's generally recommended to replace the water pump every 3-5 years or as part of major engine overhauls. Always refer to your Caterpillar engine's service manual for specific recommendations.

Q: What type of coolant should I use in my Caterpillar engine?A: It is crucial to use the coolant specified in your Caterpillar engine's operation and maintenance manual. Using the wrong type of coolant can lead to corrosion and damage to the cooling system.

Our Business

Guangzhou Pinxin Engine Co., Ltd. specializes in providing high-quality Caterpillar diesel engine assemblies and Caterpillar engine parts. We offer a wide range of components for various Caterpillar engine models, including C4.2, C4.4, C6.4, C7, C7.1, C9, C9.3, C13, C15, C18, 3306, 3406, 3408, 3512, and 3516 engines. Whether you need a complete engine assembly or specific Caterpillar engine components, we are your reliable source.

Troubleshooting Tip: Caterpillar C7 Engine OverheatingProblem: A Caterpillar C7 engine is experiencing frequent overheating, even during normal operation.

Possible Solution:

Check Coolant Level: Ensure the coolant level in the radiator and expansion tank is within the recommended range. Low coolant is a common cause of overheating.

Inspect for Leaks: Examine the radiator hoses, water pump, thermostat housing, and other cooling system components for any signs of coolant leaks. Repair any leaks immediately.

Examine the Radiator: Check the radiator fins for any blockage from debris, dirt, or insects. Clean the radiator externally with compressed air or a soft brush.

Test the Thermostat: A faulty thermostat can prevent proper coolant circulation. Consider testing or replacing the thermostat.

Check the Water Pump: A failing water pump may not circulate coolant effectively. Inspect the water pump for leaks, noise, or a loose pulley. If suspected, replace the water pump.

Verify Fan Operation: Ensure the engine cooling fan is operating correctly. Check the fan blades for damage and the fan clutch (if applicable) for proper engagement.

If the overheating issue persists after checking these points, further diagnosis by a qualified technician may be necessary.

www.caterpillar2013.com

由广数供应链(CGSC)团队提供运营方案

<!--!doctype-->