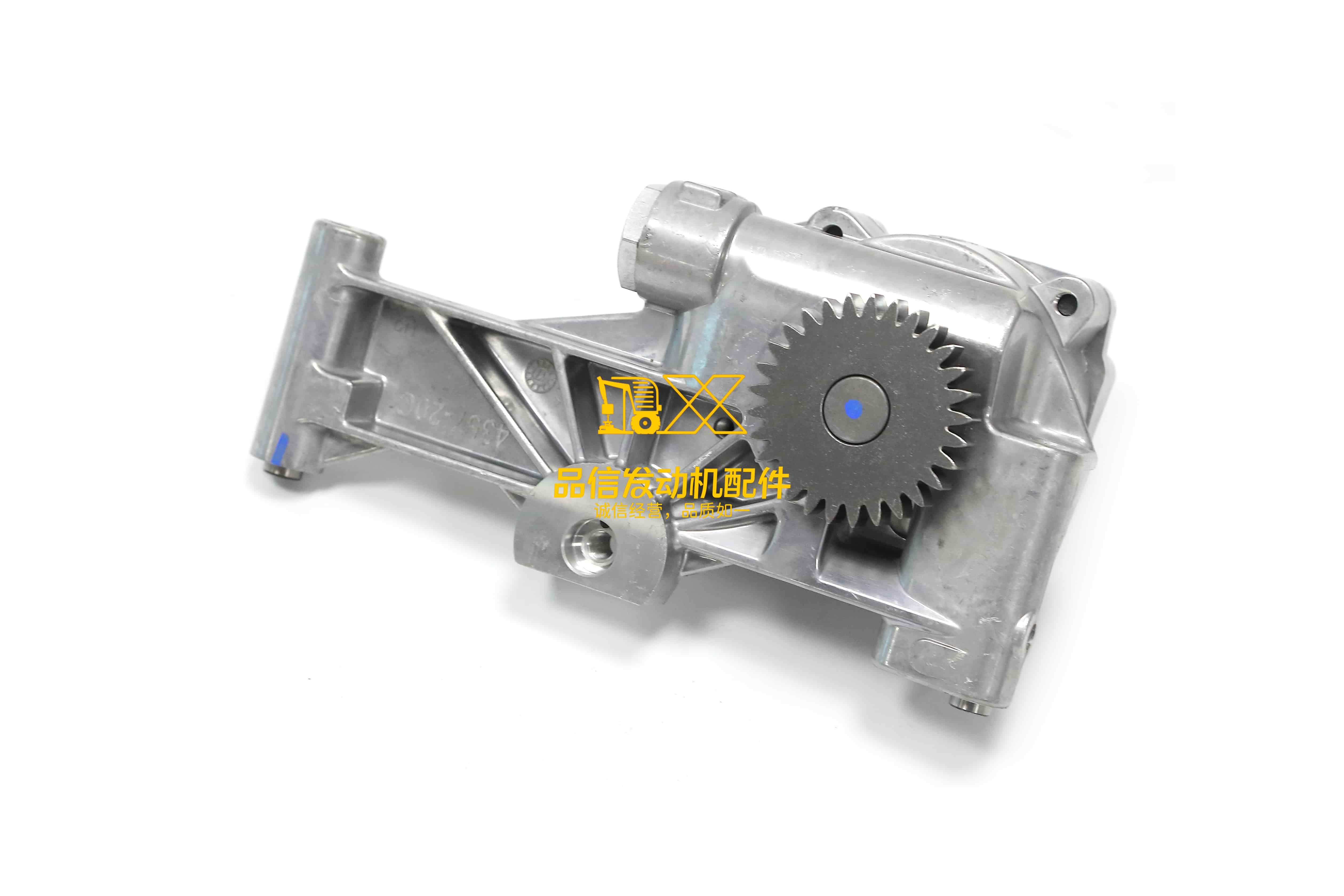

Caterpillar Cat C9 Engine Oil Pump 210-5522

Product Overview

Ensure the reliable performance and longevity of your Caterpillar C9 engine with the genuine Caterpillar Oil Pump, part number 210-5522. This essential component is engineered to deliver consistent and adequate oil pressure and flow, which is critical for the lubrication, cooling, and overall health of your engine's internal components. Designed to meet Caterpillar's stringent specifications, this oil pump provides an exact fit and dependable operation in the demanding environments where C9 engines operate.

Product Specifications

| Part Number: | 210-5522 |

| Engine Series: | Caterpillar C9 |

| Component Type: | Engine Oil Pump |

| Function: | Supplies lubricating and cooling oil throughout the engine |

| Material: | Durable, high-strength alloys |

Key Advantages & Selling Points

• Reliable Lubrication: Guarantees consistent oil pressure and flow, vital for protecting critical engine components from wear.

• Optimal Cooling: Facilitates efficient heat dissipation from engine parts, helping to maintain ideal operating temperatures.

• Engine Longevity: Proper lubrication and cooling significantly extend the lifespan of the C9 engine.

• Precise Fit & Performance: Manufactured to exact Caterpillar specifications for seamless integration and peak performance.

• Durable Construction: Built with high-quality, robust materials to withstand the harsh operating conditions of heavy equipment.

Applicable Equipment

The 210-5522 Oil Pump is suitable for a wide range of Caterpillar machines and power units equipped with the C9 engine. This includes, but is not limited to:

Excavators (e.g., 330D, 336D Series)

Dozers (e.g., D6 Series)

Wheel Loaders (e.g., 950H, 962H)

Motor Graders (e.g., 12M, 140M)

Articulated Trucks (e.g., 725, 730)

Pipelayers (e.g., PL61)

Industrial Power Units

Marine Engines

Certain On-Highway Truck Models

Please verify part compatibility with your specific machine serial number.

Application Scenarios & Case Analysis

Caterpillar C9 engines power equipment used in some of the toughest jobs on earth. A reliable oil pump like the 210-5522 is non-negotiable in these scenarios:

Heavy Construction: In excavators constantly digging and moving material, the engine is under high, sustained load. The oil pump must maintain pressure to prevent bearing damage and piston overheating. A pump failure means critical downtime on a project with tight deadlines.

Quarry & Mining: Machines haul heavy loads up steep grades in dusty, high-temperature environments. Consistent oil flow is vital for cooling and lubricating components exposed to extreme heat and potential contamination. Pump reliability is paramount for safety and productivity.

Marine Use: C9 marine engines often run for extended periods. The oil pump's performance is crucial for preventing wear caused by continuous operation and potential temperature fluctuations, ensuring the vessel's power source remains dependable at sea.

Case Example: A fleet manager for a large earthmoving company reported excessive engine wear and occasional overheating issues across several Cat 330D excavators with high hours. Investigation revealed degraded oil pumps causing marginal oil pressure during peak demand. Replacing the pumps with 210-5522 units resolved the pressure issues, normalized engine temperatures, and significantly reduced premature component wear, extending the operational life of the engines and reducing maintenance costs.

Related & Similar Products

When servicing or maintaining a C9 engine, other related components are often needed:

Oil Filters: Essential for keeping the oil clean and protecting the new pump. (Applicable Equipment: All C9 engine machines)

Engine Oil Coolers: Work alongside the pump to regulate oil temperature. (Applicable Equipment: Most C9 engine machines)

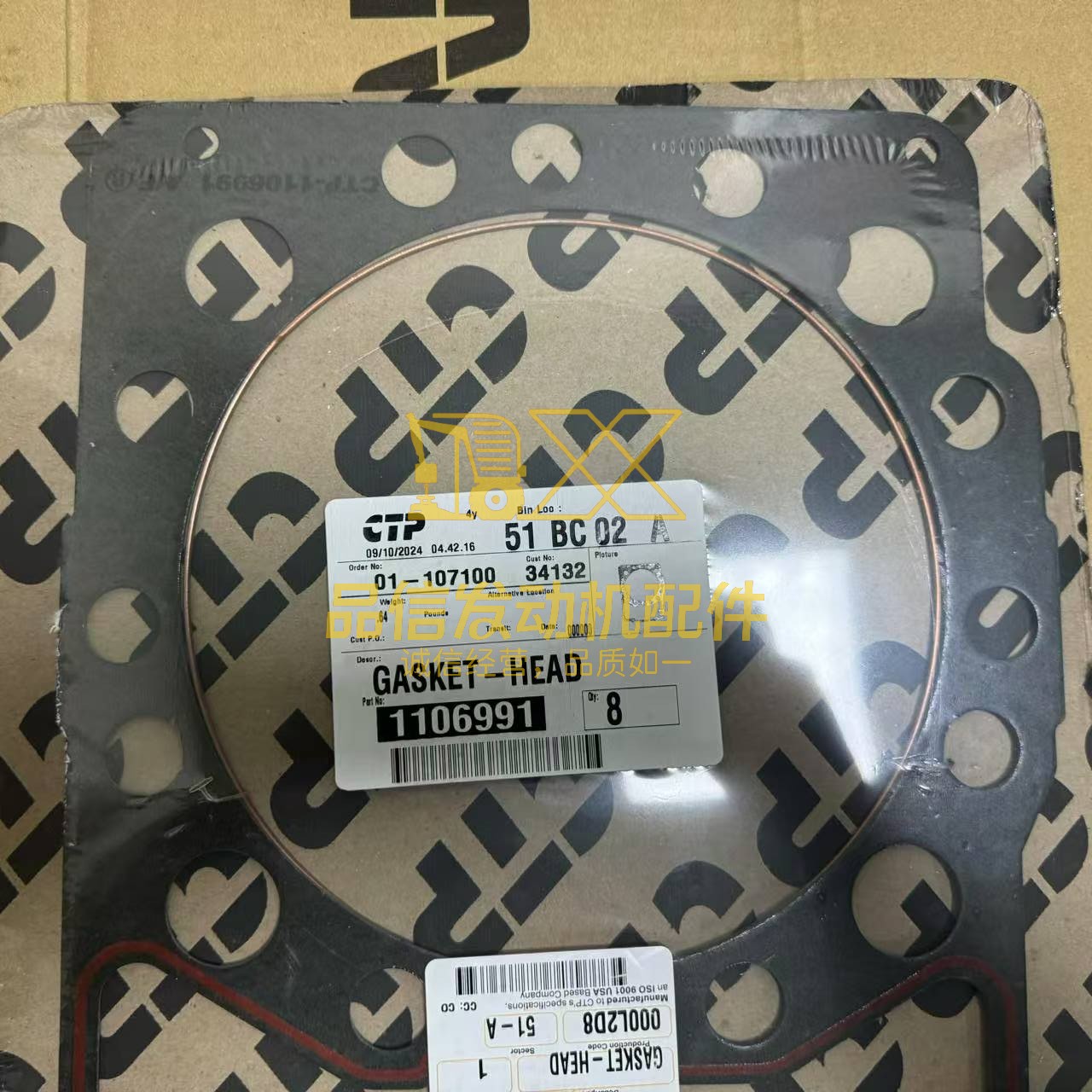

Oil Pan Gaskets & Seals: Required for reassembly after pump replacement. (Applicable Equipment: All C9 engine machines)

Crankshaft Front Seals: Often replaced during oil pump service depending on engine configuration. (Applicable Equipment: All C9 engine machines)

Installation & Maintenance: Issues and Solutions

Proper installation and ongoing maintenance are crucial for the 210-5522 oil pump's performance and lifespan.

Common Issue 1: Low or No Oil Pressure After Installation.

Solution: Verify correct oil level and viscosity. Check for air leaks in the oil pickup tube or pump inlet. Ensure the oil pump relief valve is functioning correctly and not stuck open. Double-check that the correct pump model was installed for the specific C9 engine serial number. Prime the pump if necessary according to service manual instructions.

Common Issue 2: Oil Contamination Leading to Pump Wear.

Solution: Adhere strictly to recommended oil and filter change intervals using high-quality products. Investigate the source of contamination (e.g., coolant leaks, fuel dilution, dirt ingress) and rectify it. Flush the system if necessary before installing the new pump.

Common Issue 3: Leaks Around the Pump Mounting Area.

Solution: Ensure mating surfaces are perfectly clean and free of old gasket material or debris. Use new, high-quality gaskets or seals. Follow the manufacturer's torque specifications and sequence for tightening mounting bolts.

Maintenance Tip: Regular oil analysis can detect potential issues early, such as wear metals or contamination, which helps prevent premature oil pump or engine failure.