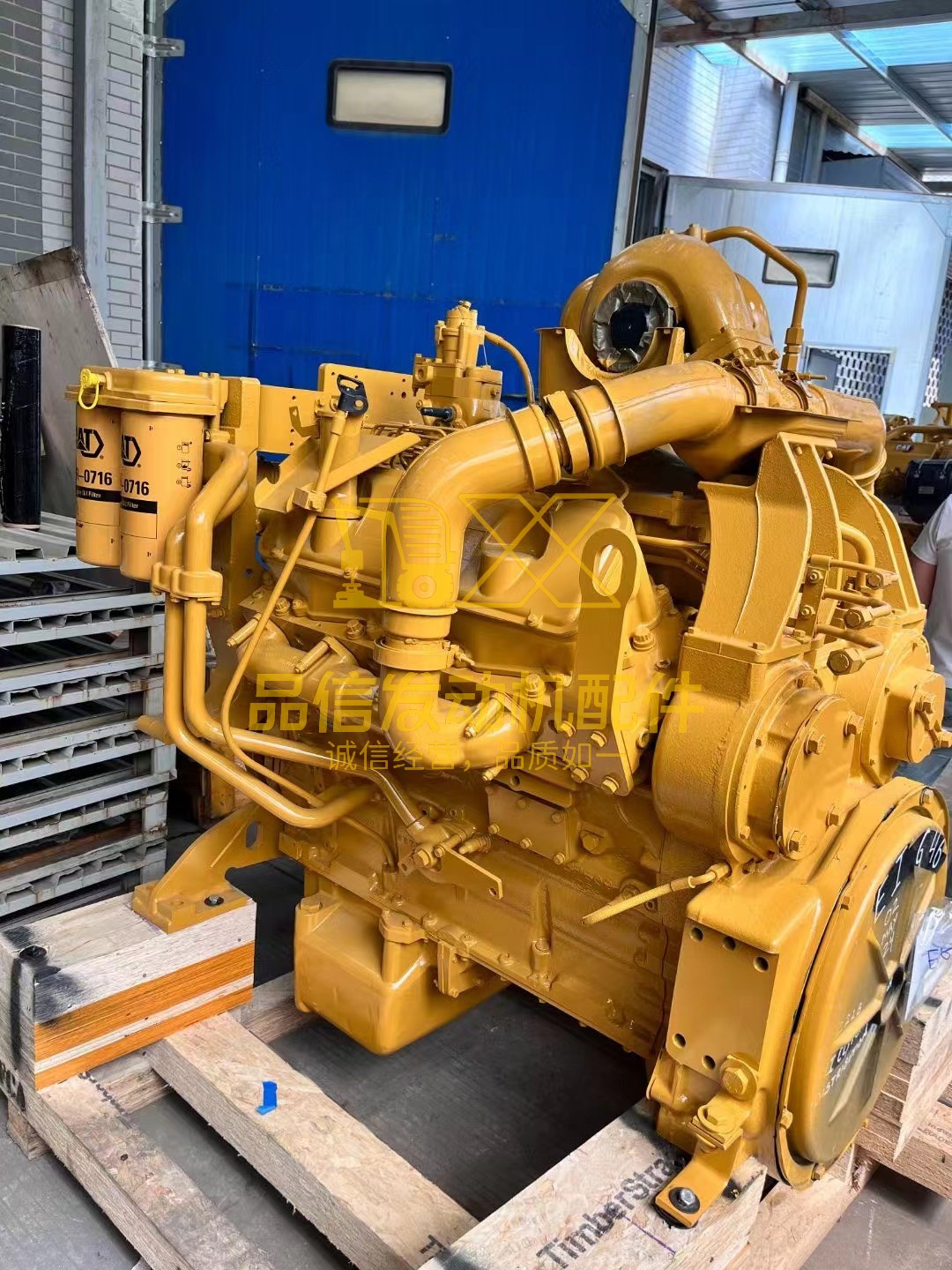

Caterpillar C9.3 Piston With Rings 357-0447 Excavator Engine Parts

Product Overview

Ensure the peak performance and longevity of your Caterpillar C9.3 engine with our high-quality replacement Piston and Ring set, part number 357-0447. Specifically engineered for Caterpillar excavators, this component is crucial for maintaining proper engine compression, optimizing power output, and reducing oil consumption. Manufactured to meet stringent quality standards, this piston and ring kit provides a reliable solution for engine rebuilds and repairs.

Product Specifications

Part Number: 357-0447

Engine Model: Caterpillar C9.3

Included: 1 x Piston, Complete Set of Piston Rings (Compression Rings, Oil Ring)

Application: Excavator Engine Parts

Material: High-strength alloy (Typical for engine pistons)

Quality: Meets or exceeds OEM specifications

Key Advantages

Optimal Engine Performance: Restores lost compression for maximum power and fuel efficiency.

Extended Engine Life: High-quality materials and precision engineering reduce wear and tear.

Reduced Oil Consumption: Effective piston rings ensure proper sealing, minimizing oil blow-by.

Precise Fit: Engineered for perfect compatibility with Caterpillar C9.3 engines.

Reliable Replacement: A durable component designed for the demanding environment of heavy machinery operation.

Applicable Equipment

This Piston with Rings set (357-0447) is designed for Caterpillar equipment powered by the C9.3 engine, commonly found in various Excavator models including, but not limited to:

Caterpillar 330D Excavator

Caterpillar 336D Excavator

Caterpillar 340D Excavator

(And other models utilizing the C9.3 engine)

Application Scenarios & Case Analysis

Caterpillar excavators equipped with the C9.3 engine are workhorses used in a variety of demanding applications:

Heavy Construction: Excavating foundations, trenching, material handling on large building sites.

Mining & Quarrying: Loading haul trucks with overburden or processed materials.

Demolition: Breaking and clearing structures.

Road Building: Earthmoving and grading for new infrastructure.

Case Example: A construction company operating a Cat 336D on a major infrastructure project noticed decreased engine power and increased exhaust smoke. Diagnostics revealed worn piston rings leading to low compression. Replacing the piston and ring set with the 357-0447 part restored the engine's compression and power output to factory specifications, allowing the excavator to efficiently handle heavy digging tasks and preventing costly downtime, thereby keeping the project on schedule and within budget.

Related & Similar Products

When undertaking engine maintenance or overhaul, you may also require other components compatible with the Caterpillar C9.3 engine. Consider the following related parts:

Cylinder Liners: Provides the cylinder wall surface for the piston to travel within. (Applicable to C9.3 engines)

Connecting Rod Bearings & Main Bearings: Crucial for the smooth rotation of the crankshaft and connecting rods. (Applicable to C9.3 engines)

Engine Gasket Kit: Contains all necessary seals and gaskets for a complete engine rebuild. (Applicable to C9.3 engines)

Valves, Guides, and Seats: Components of the cylinder head essential for proper combustion sealing. (Applicable to C9.3 engines)

Oil Pump: Ensures proper lubrication throughout the engine. (Applicable to C9.3 engines)

Installation & Maintenance Tips

Proper installation and regular maintenance are key to the performance and lifespan of engine components like pistons and rings. We recommend:

Professional Installation: Engine internal work requires specialized knowledge and tools. Always use qualified mechanics.

Cleanliness: Ensure all engine components and work areas are spotless before installation to prevent contamination.

Proper Ring Gap: Verify and adjust piston ring end gap according to service manual specifications.

Lubrication: Properly lubricate pistons, rings, and cylinder bores during assembly.

Torque Specifications: Follow manufacturer-specified torque sequences and values for all fasteners.

Regular Oil Changes: Use the recommended oil type and follow the service interval guidelines.

Monitor Engine Health: Pay attention to unusual noises, smoke, or performance changes.

Common Issues & Solutions:

Issue: Incorrect Ring Installation (e.g., upside down, wrong groove). Solution: Ensure rings are oriented correctly and placed in the designated grooves according to the service manual.

Issue: Scored Cylinder Bore. Solution: Inspect cylinder bore before installation. If scored, honing or reboring may be required before fitting new pistons and rings.

Issue: Engine Knocking after installation. Solution: Could be related to timing, fuel, or incorrect assembly. Recheck all steps and consult service manual or professional.

Issue: High Oil Consumption post-repair. Solution: Could indicate improper ring seating (requiring break-in) or other worn components like valve seals or turbocharger.