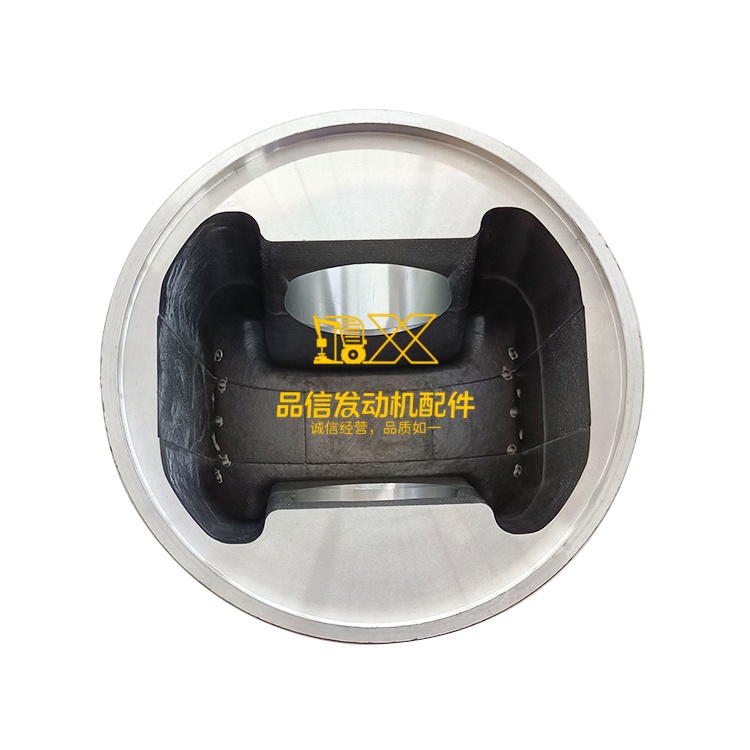

Cummins QSX15 ISX15 X15 Engine Piston - High Quality Replacement

Product Overview

This high-quality replacement piston is specifically designed for Cummins QSX15, ISX15, and X15 series engines. Manufactured to meet or exceed OEM specifications, it ensures reliable performance and durability for your heavy-duty applications. Compatible with multiple part numbers including 4298992, 3681665, 4059241, 4059345, 4923744, and 2882120, this piston is an essential component for engine repair or overhaul.

Product Specifications & Advantages

Here are some key details about this piston:

Part Numbers: 4298992, 3681665, 4059241, 4059345, 4923744, 2882120

Engine Models: Cummins QSX15, ISX15, X15

Type: Engine Piston

Material: High-strength alloy (specific composition varies by manufacturer, ensuring durability)

Compatibility: Direct replacement for specified Cummins engines

Key Advantages:

Premium Quality: Manufactured with precision engineering and high-grade materials for extended service life.

Optimal Performance: Designed to withstand high temperatures and pressures, ensuring efficient combustion and power delivery.

Perfect Fit: Engineered as a direct replacement, simplifying installation and ensuring compatibility.

Cost-Effective: Offers a reliable alternative to OEM parts without compromising on quality.

Applicable Equipment:

This piston is suitable for a wide range of heavy-duty equipment powered by Cummins QSX15, ISX15, and X15 engines, including but not limited to:

Heavy-Duty Trucks (e.g., Freightliner, Kenworth, Peterbilt, International)

Construction Machinery (e.g., Excavators, Loaders, Dozers, Cranes)

Agricultural Equipment (e.g., Large Tractors, Combines)

Power Generation Sets

Industrial Applications

Application Scenarios & Case Studies

Cummins QSX15, ISX15, and X15 engines are workhorses in demanding environments. This piston is critical for maintaining their performance in various applications:

Heavy-Duty Trucking: These engines are widely used in long-haul transportation, requiring pistons that can endure millions of cycles under varying loads and speeds. Replacing a worn piston with this high-quality part restores engine compression and fuel efficiency, crucial for operational profitability.

Case Example: A logistics company experienced reduced power and increased oil consumption in a truck with an ISX15 engine. Diagnosis revealed a worn piston. Replacing it with this compatible piston restored engine performance, allowing the truck to return to demanding routes efficiently.

Construction Sites: Equipment like large excavators and loaders rely on the power and reliability of these Cummins engines for heavy lifting and earthmoving. Pistons must withstand extreme pressures and dusty conditions.

Case Example: A construction firm had a large excavator with a QSX15 engine showing signs of blow-by. Upon inspection, a damaged piston was found. Installing this replacement piston resolved the issue, preventing downtime and maintaining project schedules.

Agricultural Operations: High-horsepower tractors and combines use these engines for demanding field work, often running for extended periods. Engine reliability is paramount during planting and harvest seasons.

Case Example: A farmer noted decreased power output from a large X15-powered tractor. Investigation revealed a failing piston seal. Replacement with this piston restored the engine's full power, ensuring the harvest was completed on time.

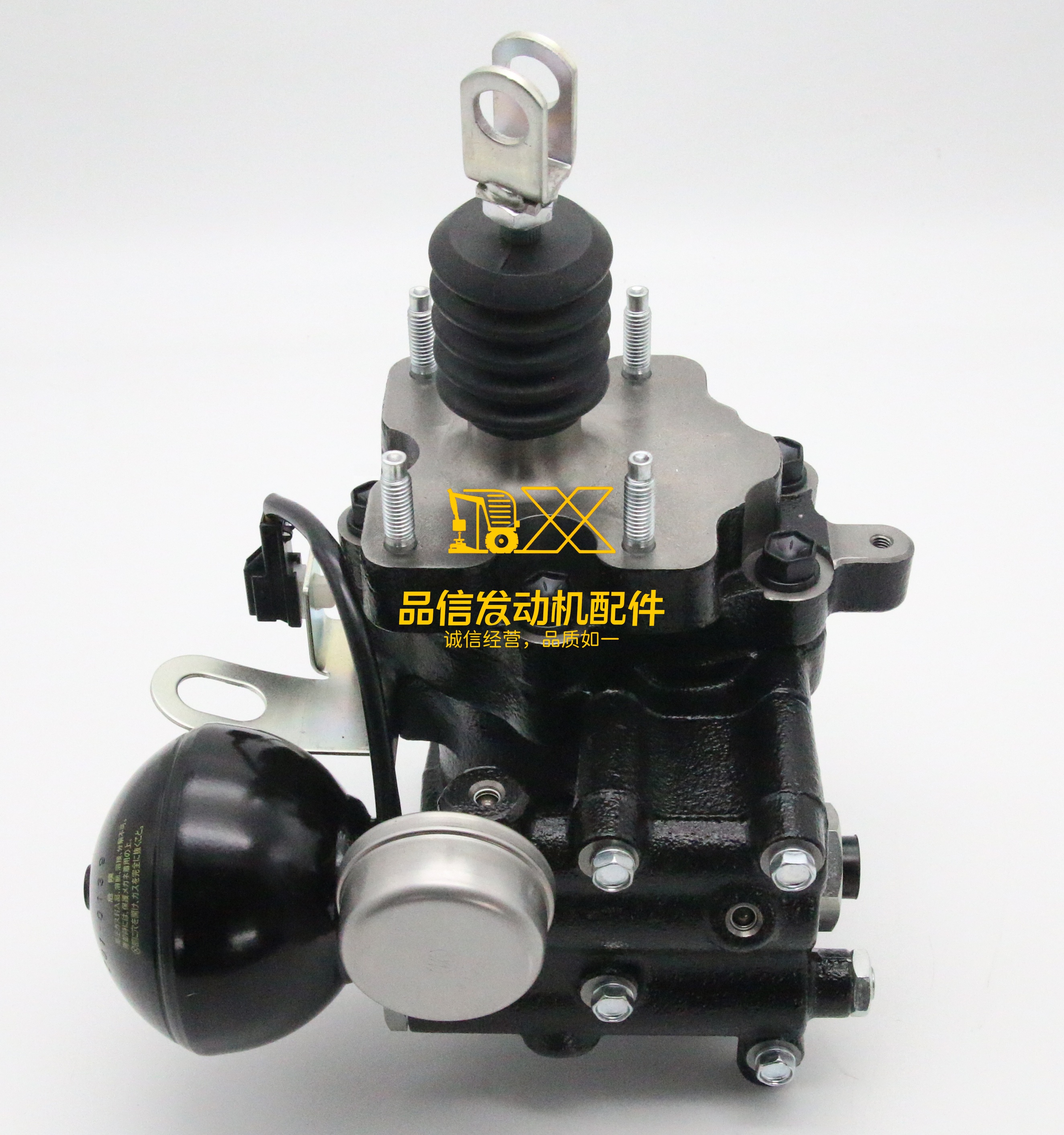

Related Products

When replacing pistons, it is often recommended to inspect and potentially replace other related engine components to ensure a complete and reliable repair. Related products include:

Piston Rings: Essential for sealing the combustion chamber and controlling oil.

Cylinder Liners/Sleeves: Provide the bore surface for the piston; often replaced during a major overhaul.

Engine Bearings: (Main and Connecting Rod Bearings) Support the crankshaft and connecting rods; critical for smooth engine rotation.

Gasket Sets: Necessary for sealing various engine components upon reassembly.

Connecting Rods: Link the piston to the crankshaft.

These related parts are also applicable to Cummins QSX15, ISX15, and X15 engines and the heavy-duty equipment listed above.

Common Installation Problems & Solutions

Installing a piston requires care and precision. Here are some common issues encountered and how to address them:

Problem: Incorrect Piston Ring Gap Setting. If the ring gap is too small, the rings can butt together when heated, causing cylinder damage. If too large, it leads to poor compression and oil consumption.

Solution: Always check the ring gap according to the engine service manual specifications using a feeler gauge before installing the rings onto the piston.

Problem: Scoring on Piston Skirt or Cylinder Bore. This can be caused by inadequate lubrication, contamination, or improper installation.

Solution: Ensure all parts are meticulously clean before assembly. Use adequate and correct type of lubrication. Carefully guide the piston assembly into the bore using a piston ring compressor tool.

Problem: Contamination (Dirt, Debris) in Engine Components. Even small particles can cause significant wear and damage.

Solution: Work in a clean environment. Thoroughly clean all engine components before reassembly. Use clean oil and filters.

Problem: Incorrect Connecting Rod Bolt Torque. Overtightening or undertightening can lead to bearing failure or rod cap loosening.

Solution: Always follow the engine service manual's specified torque values and sequence for connecting rod bolts using a calibrated torque wrench.

Always consult the specific Cummins engine service manual for detailed instructions, specifications, and torque values relevant to the QSX15, ISX15, or X15 model you are working on. Professional installation is highly recommended.