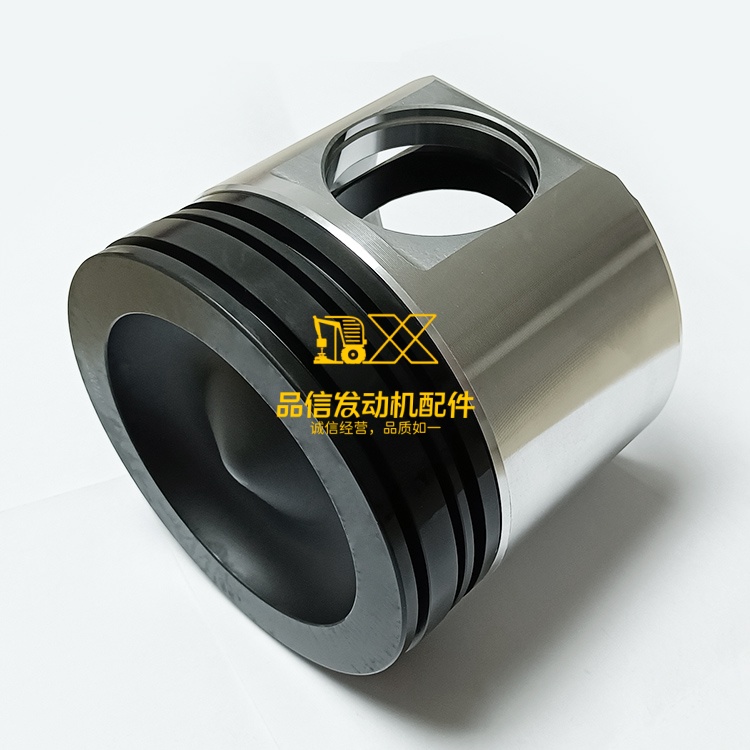

Cummins M11 ISM11 QSM11 Piston

Essential Component for Engine Performance and Reliability

Product Overview

This high-quality replacement piston is specifically designed for Cummins M11, ISM11, and QSM11 series engines. As a critical component within the combustion chamber, the piston plays a vital role in converting the energy from combustion into mechanical power. Manufactured to meet or exceed OEM specifications, this piston ensures proper fitment, optimal performance, and long-lasting durability for your Cummins engine.

Available with multiple interchange part numbers including 5469020, 4059898, 4070653, 3103753, and 4059948, this piston provides a reliable solution for engine repair and maintenance.

Product Parameters

Part Numbers: 5469020, 4059898, 4070653, 3103753, 4059948 (Interchangeable)

Engine Models: Cummins M11, ISM11, QSM11

Component Type: Piston

Material: High-strength Aluminum Alloy / Cast Iron (Note: Specific material may vary slightly by part number/application, consult technical data)

Design: Specific bowl shape and skirt design for M11/ISM11/QSM11 engines

Compatibility: Engineered for direct fit and performance match with original components

Key Advantages and Selling Points

Premium Quality: Manufactured from high-grade materials for exceptional strength and heat resistance.

Exact Fit: Precision engineered to meet OEM specifications, ensuring a seamless installation and optimal performance.

Enhanced Durability: Designed to withstand the high pressures and temperatures of heavy-duty engine operation.

Reliable Performance: Contributes to efficient combustion, proper compression, and overall engine longevity.

Cost-Effective Solution: Offers a high-quality alternative for engine repair without compromising on reliability.

Applicable Equipment

This piston is suitable for Cummins M11, ISM11, and QSM11 engines found in a variety of equipment, including:

Heavy-Duty Trucks (On-Highway)

Construction Equipment (e.g., Excavators, Dozers, Cranes)

Agricultural Machinery

Industrial Power Units

Marine Propulsion and Generator Sets

Power Generation Equipment

Application Scenarios & Case Analysis

The Cummins M11, ISM11, and QSM11 engines are workhorses in demanding applications. This piston is crucial for maintaining their performance in various scenarios:

Long-Haul Trucking: ISM11 engines are common in Class 8 trucks. A failing piston can lead to loss of power, increased oil consumption, or catastrophic engine failure, halting crucial logistics. Replacing the piston with a quality part ensures the truck can reliably cover thousands of miles.

Case Example: A transportation company experienced repeated downtime with an ISM11 truck due to piston issues. After replacing the faulty pistons with these high-quality units, the truck's performance stabilized, reducing repair costs and improving delivery schedules.

Heavy Construction: QSM11 engines power large construction equipment like excavators and cranes operating in harsh conditions. Piston integrity is vital for the high torque and power required for digging and lifting. A damaged piston severely impacts productivity.

Case Example: On a major infrastructure project, a QSM11 excavator started showing signs of blow-by. Inspection revealed a worn piston. Replacing it promptly prevented further damage and kept the critical excavation work on schedule.

Industrial Power: M11 and QSM11 engines are used in various industrial applications, including pumps, compressors, and generators, often running continuously. Reliable piston performance is essential for uninterrupted operation and preventing costly production stops.

Case Example: A manufacturing plant relied on a QSM11-powered generator for backup power. During testing, it failed to reach full output. Diagnosis traced the issue to a compression problem caused by a faulty piston. Replacement restored the generator's full capability, securing the plant's power supply.

Related and Similar Products

When replacing a piston, it's often recommended to inspect or replace related components for a complete and reliable engine rebuild or repair. Other parts for Cummins M11, ISM11, and QSM11 engines include:

Piston Rings: Sealing the piston to the cylinder wall (Essential replacement with new pistons). Applicable to M11, ISM11, QSM11 engines in all listed equipment.

Cylinder Liners / Sleeves: The surface the piston moves against. May require replacement if worn or damaged. Applicable to M11, ISM11, QSM11 engines.

Connecting Rod Bearings: Support the connection between the piston and crankshaft. Applicable to M11, ISM11, QSM11 engines.

Main Bearings: Support the crankshaft rotation. Applicable to M11, ISM11, QSM11 engines.

Gasket Kits: Provide seals for various engine components during assembly (e.g., head gasket, oil pan gasket). Applicable to M11, ISM11, QSM11 engines.

We offer a full range of high-quality engine parts for these Cummins models to ensure your repair or overhaul is successful.

Common Installation Issues and Solutions

Proper installation is crucial for the longevity and performance of the piston and engine. Here are common issues encountered during piston installation and how to address them:

Issue: Incorrect Piston Ring Gap. If the ring gap is too small, the rings can butt together when heated, causing scoring. If too large, compression and oil control suffer.

Solution: Always check and file piston ring end gaps according to the engine service manual specifications for your specific engine serial number.

Issue: Dirt and Debris Contamination. Any foreign material in the cylinder or on bearing surfaces can cause rapid wear or catastrophic failure.

Solution: Ensure all components and work areas are meticulously clean before assembly. Use lint-free cloths. Lubricate parts with clean engine oil during assembly.

Issue: Improper Connecting Rod Bolt Torque. Under-torquing can lead to bearing failure or cap separation. Over-torquing can stretch bolts or distort the connecting rod.

Solution: Use a calibrated torque wrench and follow the manufacturer's specified torque sequence and values precisely.

Issue: Installing Piston Backwards. Some pistons have a specific orientation (e.g., indicating the front of the engine). Incorrect installation affects performance and can cause damage.

Solution: Refer to the engine service manual for correct piston orientation and markings. Double-check before insertion.

Issue: Damaged Cylinder Bore. Installing a new piston in a scored or out-of-spec cylinder bore will quickly damage the new piston and rings.

Solution: Thoroughly inspect the cylinder bore for wear, scoring, or tapering. Hone or bore the cylinder as necessary before installing the new piston.

Always consult the official Cummins service manual for your specific engine model for detailed installation procedures and specifications.