Cummins 6CT8.3 & QSC8.3 Piston Kit

Essential Engine Components for Reliable Performance

Part Numbers: 3942106, 3943367, 3943446, 3800316, 3800318, 3800319, 3800320

Product Overview

This high-quality piston kit is specifically designed for Cummins 6CT8.3 and QSC8.3 series engines. It provides the critical components needed for a complete piston replacement during engine overhaul or repair, ensuring renewed performance and longevity. Manufactured to meet or exceed OEM specifications, these pistons and associated parts are built for demanding applications.

Key Product Parameters

Engine Models: Cummins 6CT8.3, QSC8.3

Bore Diameter: Typically 114mm (4.49 inches)

Stroke: Typically 135mm (5.32 inches)

Piston Type: Varies by specific part number, includes designs for different compression ratios and applications.

Material: High-strength Aluminum Alloy or Steel (depending on specific part number/application)

Includes: Piston, Piston Pin, Retainers (Circlips). Piston Rings are typically sold separately but may be included in some kit variations.

Part Numbers Covered: 3942106, 3943367, 3943446, 3800316, 3800318, 3800319, 3800320

Note: Specific parameters may vary slightly based on the exact part number and engine build. Always verify compatibility.

Advantages & Selling Points

Optimal Performance: Restores engine compression and power output.

Exceptional Durability: Manufactured from robust materials to withstand high temperatures and pressures.

Precise Fit: Engineered to exact Cummins specifications for seamless integration.

Reliable Quality: Produced under strict quality control standards.

Broad Compatibility: Covers multiple essential piston kit part numbers for the 6CT8.3 and QSC8.3 platforms.

Applicable Equipment

The Cummins 6CT8.3 and QSC8.3 engines are workhorses found in a wide range of heavy-duty equipment, including:

Construction Machinery: Excavators, Wheel Loaders, Dozers, Graders, Compactors (e.g., some models from Caterpillar, Komatsu, Volvo, John Deere - *note: compatibility depends on engine*).

Agricultural Equipment: Tractors, Combines, Harvesters.

Marine Applications: Propulsion and Generator Sets.

Industrial Equipment: Power Units, Pumps, Compressors, Generator Sets.

Buses and Trucks: Medium to heavy-duty commercial vehicles.

Application Scenarios & Case Studies

These piston kits are vital for maintaining the performance and reliability of equipment operating in demanding environments:

Scenario 1: Construction Site Excavator

An excavator powered by a Cummins 6CT8.3 engine experiences a loss of power and increased oil consumption, symptoms often linked to worn pistons and rings. Replacing the piston kit restores cylinder compression, improving fuel efficiency and digging power, minimizing downtime on critical infrastructure projects.

Scenario 2: Agricultural Tractor in Harvest Season

A tractor with a QSC8.3 engine is essential for timely harvesting. Engine performance issues during peak season can lead to significant losses. Installing a new piston kit ensures the engine runs reliably at full load for extended periods, crucial for completing the harvest before weather changes.

Scenario 3: Marine Generator Set

Reliable power is critical on commercial vessels using Cummins 6CT8.3 generator sets. A failing piston can lead to unstable power supply. Replacing the piston kit ensures the generator provides consistent, reliable electrical power for all onboard systems, vital for navigation and operations.

Related & Similar Products

Customers often purchase the following parts when replacing pistons in Cummins 6CT8.3 / QSC8.3 engines:

Piston Rings: (Specific part numbers apply) - Seal the piston to the cylinder wall, critical for compression and oil control. Applicable to all equipment using these engines.

Cylinder Liners / Sleeves: (Specific part numbers apply) - The surface the piston moves against. Often replaced with pistons. Applicable to all equipment.

Engine Bearings: (Main, Rod, Thrust bearings) - Support the crankshaft and connecting rods. Essential for engine rotation. Applicable to all equipment.

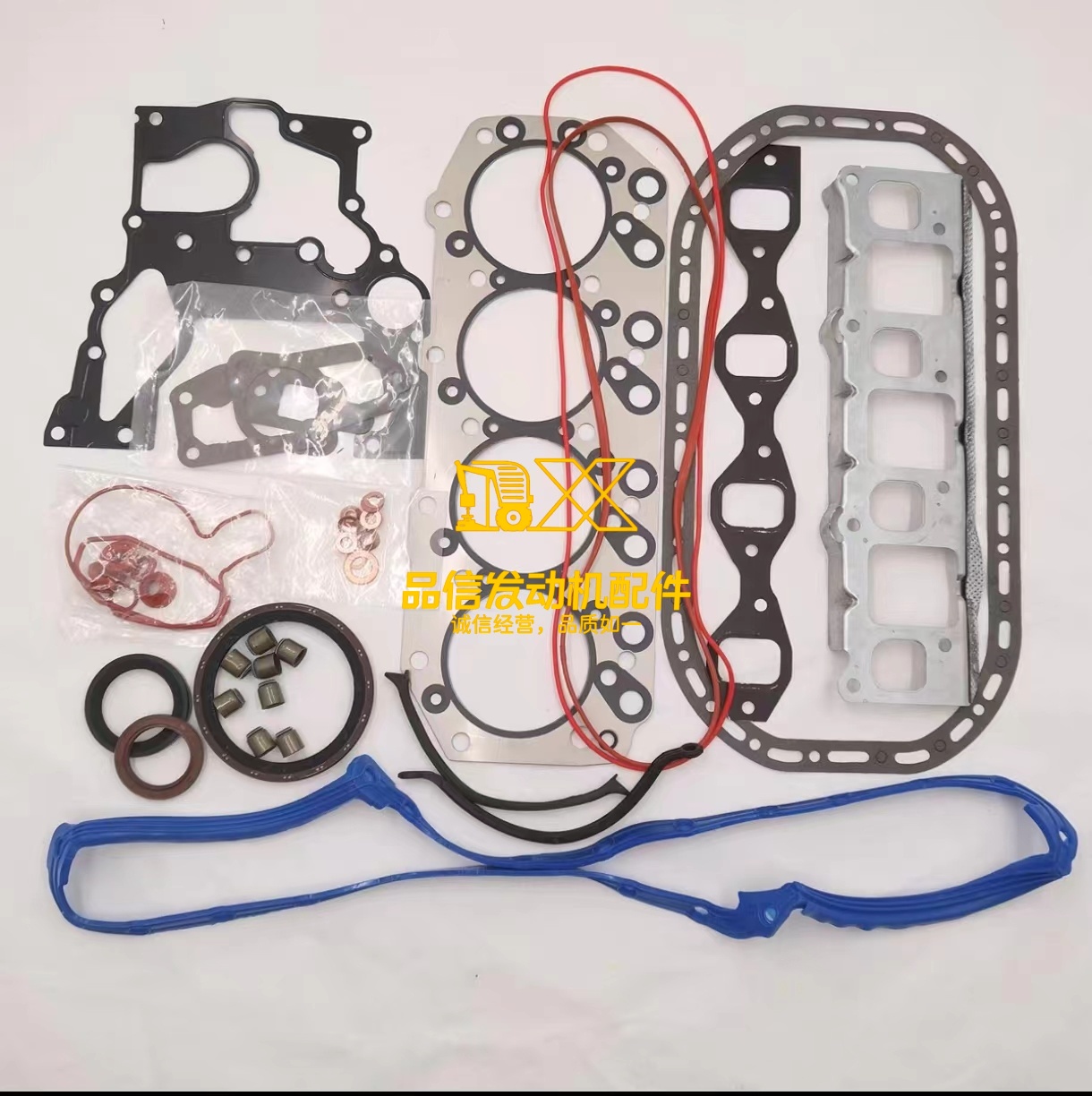

Gasket Sets: (Upper and Lower sets) - Seal various engine components. Necessary for reassembly. Applicable to all equipment.

Connecting Rods: (Specific part numbers apply) - Link the piston to the crankshaft. Applicable to all equipment.

Common Installation Problems & Solutions

Proper installation is crucial for piston kit longevity. Here are common issues and how to avoid them:

Problem: Incorrect Piston Orientation. Pistons often have a specific direction (e.g., towards the front of the engine).

Solution: Always check markings on the piston crown or skirt and consult the service manual for correct orientation.

Problem: Improper Piston Ring Installation (Incorrect gap, broken rings). Incorrectly installed rings lead to poor compression and oil control.

Solution: Ensure ring gaps are correctly measured and staggered according to the manual. Use a ring expander tool carefully to avoid breakage.

Problem: Damage to Cylinder Wall during Installation. Forcing the piston can scratch the cylinder liner.

Solution: Use a proper piston ring compressor. Ensure the cylinder wall is clean and lubricated. Insert the piston smoothly and squarely.

Problem: Incorrect Torque on Connecting Rod Bolts. Overtightening or undertightening can cause bearing or rod failure.

Solution: Always use a torque wrench and follow the manufacturer's specified torque values and sequence precisely.

Problem: Lack of Cleanliness. Debris in the cylinder or on parts can cause significant engine damage.

Solution: Ensure all parts and engine surfaces are meticulously clean before assembly. Use lint-free cloths.