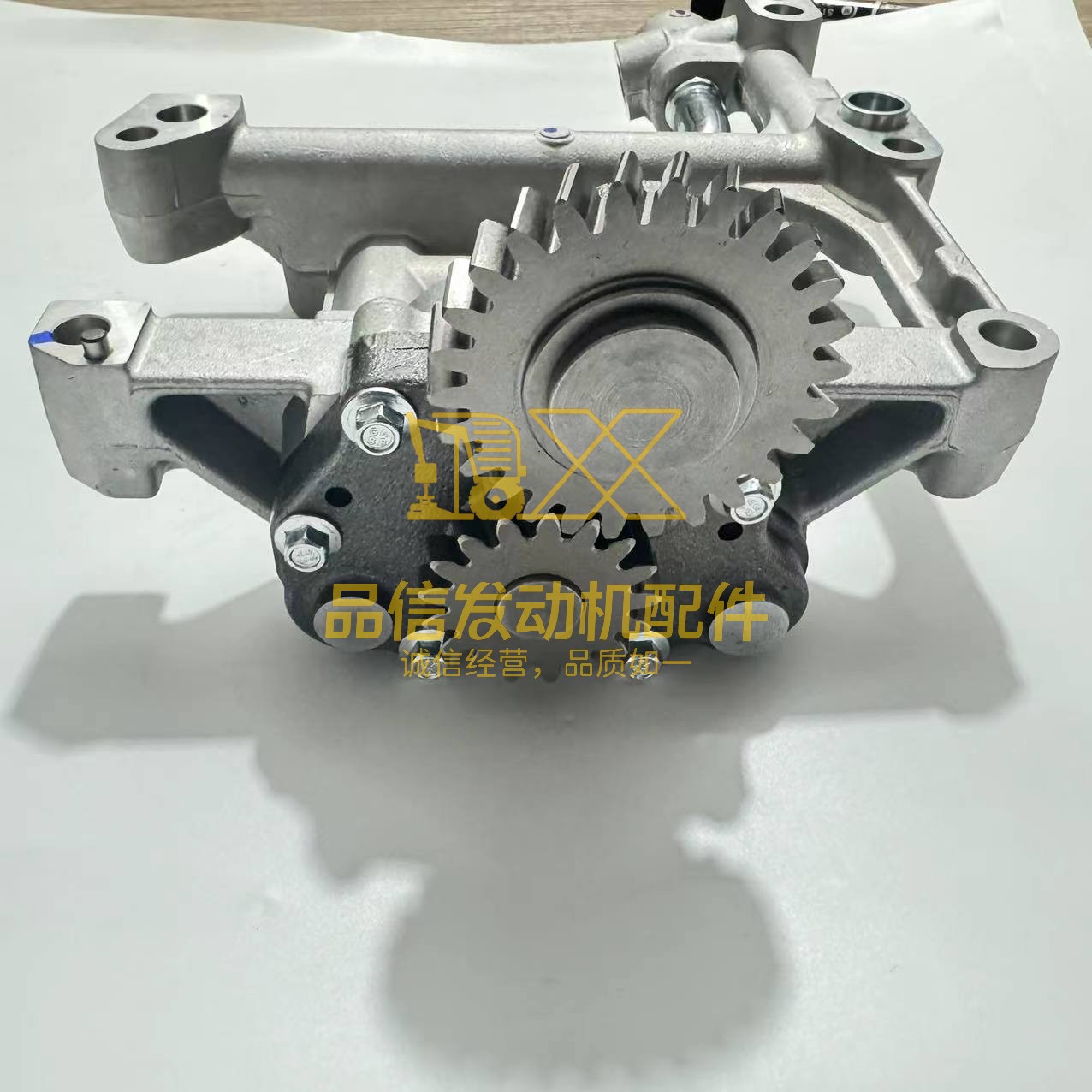

Caterpillar Oil Pump 225-8329 - High-Performance and Reliable

Ensure the optimal lubrication and performance of your Caterpillar engines with the Oil Pump 225-8329. This high-quality oil pump is specifically designed as a replacement part for a wide range of Caterpillar engine models, including the 3054C, 3054E, and C4.4 series, as well as equipment models like 414E, 416D, 416E, 416F, 420D, 420E, 420F, 422E, 422F, 424D, 428D, 428E, 428F, 430D, 430E, 430F, 432D, 432E, 432F, 434E, 434F, 442D, 442E, 444E, 444F, and 450E.

Product Information

The Oil Pump 225-8329 is a vital component for maintaining the health and longevity of your Caterpillar machinery. It is engineered to provide consistent and reliable oil pressure, ensuring critical engine parts are properly lubricated to prevent wear and tear. This oil pump is manufactured to meet or exceed OEM standards, guaranteeing a perfect fit and optimal performance.

Key Features:

Part Number: 225-8329

Direct replacement for Caterpillar oil pumps

Ensures consistent oil pressure for engine protection

High-quality construction for durability and reliability

Designed for Caterpillar engine models: 3054C, 3054E, C4.4

Compatible with Caterpillar equipment models: 414E, 416D, 416E, 416F, 420D, 420E, 420F, 422E, 422F, 424D, 428D, 428E, 428F, 430D, 430E, 430F, 432D, 432E, 432F, 434E, 434F, 442D, 442E, 444E, 444F, 450E

Caterpillar (卡特彼勒) Engine Parts - Ensuring Engine Longevity

At Guangzhou Pinxin Engine Co., Ltd., we specialize in providing top-quality Caterpillar diesel engine assemblies and 零部件 (parts). Our extensive inventory includes a wide range of engine models, such as C4.2, C4.4, C6.4, C7, C7.1, C9, C9.3, C13, C15, C18, 3306, 3406, 3408, 3512, and 3516 Caterpillar engines. We are committed to supplying reliable and durable parts to keep your Caterpillar equipment running smoothly.

Caterpillar Engine Part Name Explanations

Understanding the components of your Caterpillar engine is crucial for maintenance and repair. Here are 10 common Caterpillar engine parts explained:

Fuel Injector (燃油喷油器): Delivers fuel to the engine cylinder for combustion. Located on the cylinder head. Example: Caterpillar C4.4 Engine Fuel Injector, Part Number: 326-4700.

Turbocharger (涡轮增压器): Increases engine power and efficiency by forcing more air into the combustion chamber. Typically mounted on the exhaust manifold. Example: Caterpillar C7 Engine Turbocharger, Part Number: 295-9125.

Water Pump (水泵): Circulates coolant to regulate engine temperature. Usually located at the front of the engine, driven by the engine belt. Example: Caterpillar 3306 Engine Water Pump, Part Number: 4W5239.

Oil Filter (机油滤清器): Removes contaminants from the engine oil to ensure clean lubrication. Screw-on type, located externally on the engine block. Example: Caterpillar C9 Engine Oil Filter, Part Number: 1R0739.

Piston (活塞): A moving component within the cylinder that compresses the air-fuel mixture and transmits force to the crankshaft. Located inside the engine cylinder. Example: Caterpillar C15 Engine Piston, Part Number: 245-2722.

Cylinder Liner (气缸套): A replaceable sleeve within the engine block that forms the cylinder bore. Example: Caterpillar 3406 Engine Cylinder Liner, Part Number: 1W5400.

Crankshaft (曲轴): Converts the linear motion of the pistons into rotational motion. Located at the bottom of the engine block. Example: Caterpillar C18 Engine Crankshaft, Part Number: 379-7350.

Camshaft (凸轮轴): Controls the opening and closing of the engine valves. Located in the cylinder head. Example: Caterpillar C6.4 Engine Camshaft, Part Number: 299-9183.

Connecting Rod (连杆): Connects the piston to the crankshaft, transmitting force. Located inside the engine block, connecting pistons to the crankshaft. Example: Caterpillar C7.1 Engine Connecting Rod, Part Number: 388-7335.

Engine Valve (发动机气门): Controls the intake of air and exhaust of gases from the cylinder. Located in the cylinder head. Example: Caterpillar 3512 Engine Engine Valve, Part Number: 142-7443 (Intake Valve).

Common Questions about Caterpillar Engine Parts

What are the signs of a failing oil pump in a Caterpillar engine?

Low oil pressure warning light, unusual engine noises, overheating, and decreased engine performance can indicate an oil pump failure. Regular maintenance and oil pressure checks are crucial.

How often should I replace Caterpillar engine oil filters?

It is generally recommended to replace Caterpillar engine oil filters at every oil change interval. Refer to your Caterpillar equipment's operation and maintenance manual for specific recommendations.

Where can I buy genuine Caterpillar engine parts?

Genuine Caterpillar engine parts and components, including oil pumps, can be purchased from authorized Caterpillar dealers and reputable parts suppliers like Guangzhou Pinxin Engine Co., Ltd.. Ensure you source parts from trusted suppliers to guarantee quality and compatibility.

Our Business - Guangzhou Pinxin Engine Co., Ltd.

Guangzhou Pinxin Engine Co., Ltd. is your trusted partner for Caterpillar diesel engine solutions. We specialize in the sales and distribution of Caterpillar diesel engine assemblies and 零部件 (parts). With years of experience in the industry, we are dedicated to providing our customers with genuine, high-performance Caterpillar products. Our extensive product range covers engine models including C4.2, C4.4, C6.4, C7, C7.1, C9, C9.3, C13, C15, C18, 3306, 3406, 3408, 3512, 3516, and more. Whether you need a complete engine assembly or individual parts, Guangzhou Pinxin Engine Co., Ltd. is here to meet your needs with quality products and exceptional service.

Common Caterpillar Equipment Failure and Solution

Problem: Engine Overheating in Caterpillar 420F Backhoe Loader

Description: A Caterpillar 420F backhoe loader experiences frequent engine overheating, especially under heavy load or during hot weather. The temperature gauge rises rapidly, and steam may be visible.

Possible Causes:

Troubleshooting and Solution:

Check Coolant Level: Allow the engine to cool down completely. Carefully check the coolant level in the radiator and expansion tank. If low, check for leaks and replenish coolant to the correct level.

Inspect Radiator: Examine the radiator for external blockage from dirt, debris, or bent fins. Clean the radiator externally using compressed air or a soft brush. If overheating persists, internal radiator corrosion or blockage may require professional radiator service or replacement.

Test Thermostat: A faulty thermostat can prevent proper coolant circulation. A mechanic can test the thermostat to ensure it opens at the correct temperature. Replace if necessary.

Examine Water Pump: Listen for unusual noises from the water pump area. Inspect for coolant leaks around the water pump. A failing water pump will need replacement.

Check Fan Belt: Ensure the fan belt is properly tensioned and in good condition. Replace a loose, cracked, or damaged fan belt.

Preventive Measures: Regular maintenance, including coolant flushes, radiator cleaning, and inspection of belts and hoses, can help prevent engine overheating issues.

Visit our website for more Caterpillar engine parts:

www.caterpillar2013.com

由

<!--!doctype-->