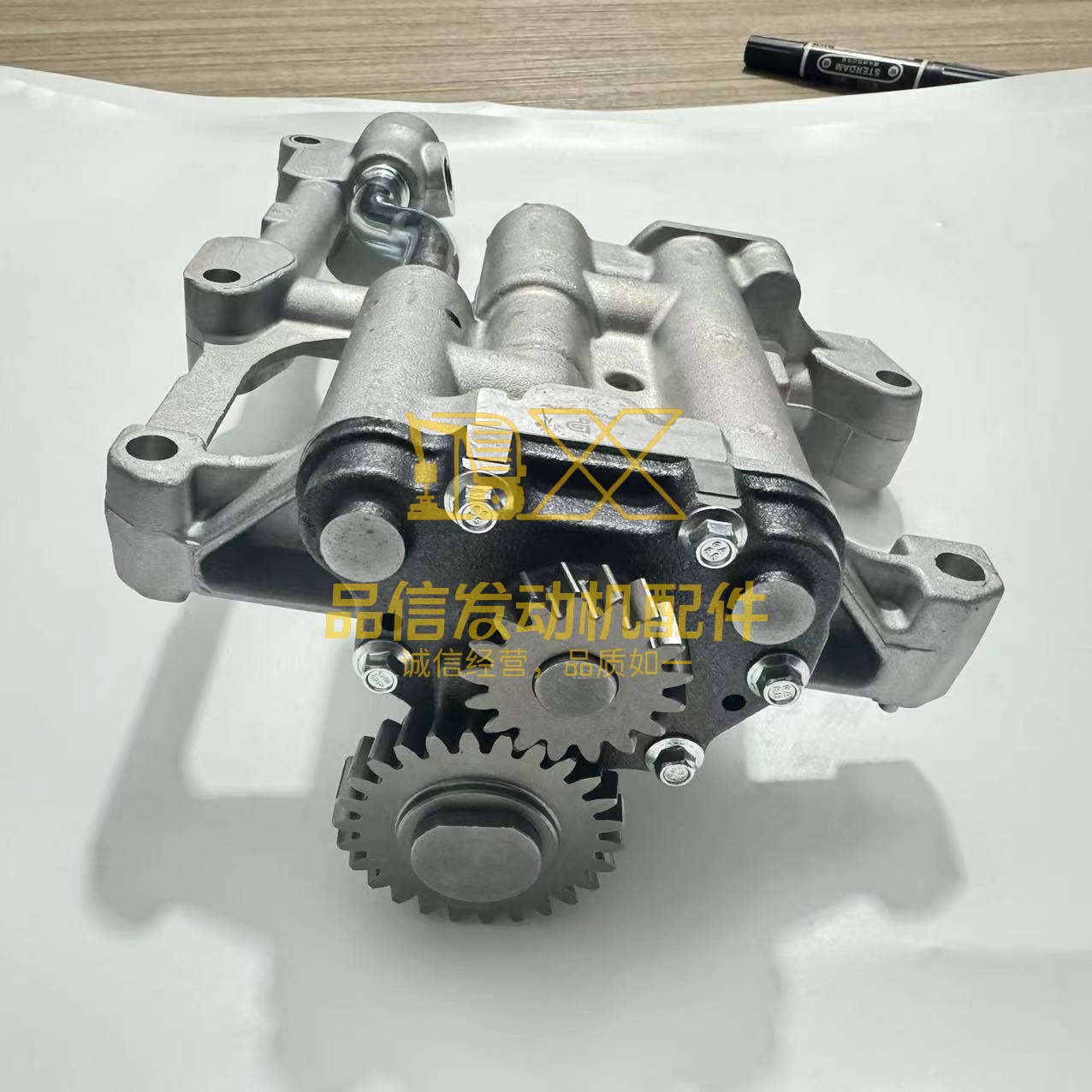

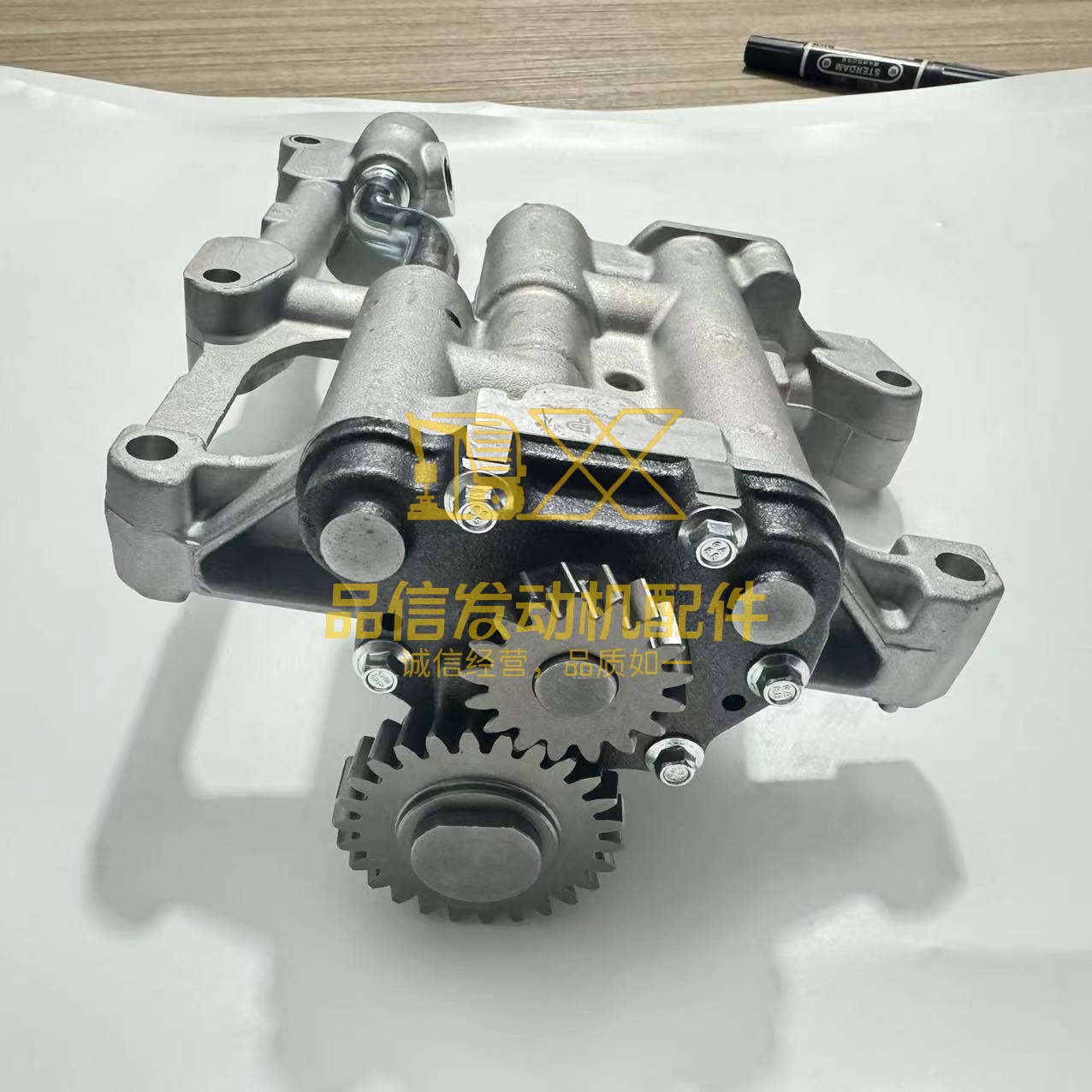

Oil Pump 4132F071 for Perkins EngineOil Pump 4132F071 for Perkins (珀金斯) Engine - High-Quality Replacement Part

Ensure the optimal lubrication and performance of your Perkins (珀金斯) engine with our premium Oil Pump 4132F071. This oil pump is specifically designed as a high-quality replacement part for a range of Perkins (珀金斯) engine models, including:

The Oil Pump 4132F071 is crucial for maintaining consistent oil pressure, which is vital for the longevity and efficiency of your Perkins (珀金斯) engine. This durable and reliable oil pump ensures that critical engine components are properly lubricated, reducing friction and wear, and preventing costly engine failures.

Guangzhou Pinxin Engine Co., Ltd. (广州品信发动机有限公司) - Your Trusted Source for Diesel Engine Parts

As a leading provider in the diesel engine parts industry, Guangzhou Pinxin Engine Co., Ltd. (广州品信发动机有限公司) specializes in Caterpillar diesel engine assemblies and parts. We offer a comprehensive range of components for Caterpillar (卡特彼勒) engines, including models such as:

Our commitment is to provide high-quality replacement parts that meet or exceed OEM standards, ensuring your machinery operates at peak performance. Beyond Caterpillar (卡特彼勒) parts, we also offer parts for other engine brands, including this premium Oil Pump 4132F071 for Perkins (珀金斯) engines.

Understanding Caterpillar (卡特彼勒) Engine Components

To help you better understand your Caterpillar (卡特彼勒) engine, here are explanations of 10 common parts:

Fuel Injector (燃油喷油器): Located in the cylinder head, fuel injectors spray fuel into the combustion chamber.

Example: Caterpillar (卡特彼勒) C7 Engine Fuel Injector, Part Number: 238-8533

Turbocharger (涡轮增压器): Installed on the exhaust manifold, the turbocharger increases engine power by forcing more air into the cylinders.

Example: Caterpillar (卡特彼勒) 3406 Engine Turbocharger, Part Number: 0R7224

Water Pump (水泵): Typically mounted at the front of the engine, the water pump circulates coolant to regulate engine temperature.

Example: Caterpillar (卡特彼勒) C9 Engine Water Pump, Part Number: 228-9129

Oil Filter (机油滤清器): Usually screwed onto the engine block, the oil filter removes contaminants from the engine oil.

Example: Caterpillar (卡特彼勒) C15 Engine Oil Filter, Part Number: 1R0770

Piston (活塞): Operating within the cylinder, the piston moves up and down to compress air and transmit force from combustion.

Example: Caterpillar (卡特彼勒) C4.4 Engine Piston, Part Number: 224-4451

Cylinder Liner (缸套): Fitted inside the engine block, the cylinder liner forms the inner wall of the cylinder.

Example: Caterpillar (卡特彼勒) 3306 Engine Cylinder Liner, Part Number: 2W6000

Crankshaft (曲轴): Located at the bottom of the engine block, the crankshaft converts the linear motion of the pistons into rotational motion.

Example: Caterpillar (卡特彼勒) C18 Engine Crankshaft, Part Number: 379-7910

Camshaft (凸轮轴): Positioned in the cylinder head, the camshaft controls the opening and closing of the engine valves.

Example: Caterpillar (卡特彼勒) C6.4 Engine Camshaft, Part Number: 319-2530

Connecting Rod (连杆): Connects the piston to the crankshaft, transmitting force between them.

Example: Caterpillar (卡特彼勒) C7.1 Engine Connecting Rod, Part Number: 388-7345

Engine Valve (气门): Situated in the cylinder head, engine valves control the intake of air and exhaust of gases from the combustion chamber.

Example: Caterpillar (卡特彼勒) 3516 Engine Engine Valve, Part Number: 149-7441

Common Questions about Diesel Engine Parts

Frequently Asked Questions

What are the common causes of Caterpillar (卡特彼勒) engine overheating?

Overheating in Caterpillar (卡特彼勒) engines can be caused by low coolant levels, a faulty thermostat, a malfunctioning water pump, or a clogged radiator. Regular maintenance and coolant checks are essential to prevent overheating.

How often should I replace Caterpillar (卡特彼勒) engine oil and filters?

The replacement interval for engine oil and filters in Caterpillar (卡特彼勒) engines depends on the engine model and operating conditions. Refer to your Caterpillar (卡特彼勒) engine's operation and maintenance manual for specific recommendations. Generally, oil and filters should be changed every 250 to 500 hours of operation or every 6 months, whichever comes first.

Where can I find reliable Caterpillar (卡特彼勒) engine parts?

For reliable Caterpillar (卡特彼勒) engine parts, you can trust Guangzhou Pinxin Engine Co., Ltd. (广州品信发动机有限公司). We provide a wide range of high-quality Caterpillar (卡特彼勒) engine parts and components to meet your needs.

Our Business at Guangzhou Pinxin Engine Co., Ltd. (广州品信发动机有限公司)

Guangzhou Pinxin Engine Co., Ltd. (广州品信发动机有限公司) is dedicated to supplying top-grade Caterpillar (卡特彼勒) diesel engine parts and assemblies to customers worldwide. We offer:

Genuine Caterpillar (卡特彼勒) Parts

OEM Replacement Parts

Engine Overhaul Kits

Individual Engine Components

Expert consultation and support

Whether you need a complete engine assembly or a single component like the Oil Pump 4132F071, Guangzhou Pinxin Engine Co., Ltd. (广州品信发动机有限公司) is your reliable partner.

Troubleshooting Caterpillar (卡特彼勒) Equipment: Hydraulic System Failure

Problem: Caterpillar (卡特彼勒) Excavator - Slow Hydraulic Response and Weak Digging Power

Description: A common issue in Caterpillar (卡特彼勒) excavators is a slow or weak hydraulic response, leading to reduced digging power. This can manifest as sluggish movement of the boom, arm, or bucket, and an overall decrease in operational efficiency.

Possible Causes:

Low Hydraulic Fluid Level: Insufficient hydraulic fluid can lead to pump cavitation and reduced system pressure.

Contaminated Hydraulic Fluid: Dirt, debris, or water in the hydraulic fluid can damage components and restrict flow.

Clogged Hydraulic Filters: Blocked filters restrict fluid flow, reducing system pressure and performance.

Faulty Hydraulic Pump: Wear or damage to the hydraulic pump can reduce its efficiency and output pressure.

Internal Leaks: Leaks within hydraulic cylinders or valves can cause pressure loss and slow operation.

Troubleshooting and Solutions:

Check Hydraulic Fluid Level: Inspect the hydraulic fluid reservoir and ensure the fluid level is within the recommended range. Top up if necessary, using the correct type of hydraulic fluid specified by Caterpillar (卡特彼勒).

Inspect Hydraulic Fluid Condition: Examine the hydraulic fluid for contamination. If the fluid appears milky, dark, or contains debris, drain and replace it. Flush the hydraulic system if contamination is severe.

Replace Hydraulic Filters: Change the hydraulic filters according to the Caterpillar (卡特彼勒) maintenance schedule. Clogged filters are a common cause of hydraulic issues.

Test Hydraulic Pump Pressure: Use a pressure gauge to test the hydraulic pump's output pressure. Compare the reading to the manufacturer's specifications. A low pressure reading may indicate a faulty pump requiring repair or replacement.

Inspect for Leaks: Visually inspect hydraulic cylinders, hoses, and valves for external leaks. Internal leaks are harder to detect but can sometimes be identified by unusual heat buildup or noise in specific hydraulic components. Cylinder seal leaks often require cylinder disassembly and seal replacement. Valve leaks may necessitate valve repair or replacement.

Preventive Measures: Regular maintenance, including fluid and filter changes, and system inspections, are crucial for preventing hydraulic system failures and ensuring optimal performance of your Caterpillar (卡特彼勒) equipment.

Visit our website to explore our full range of products:

www.caterpillar2013.com

<!--!doctype-->